Technology has further enhanced the whole process, with manufacturing now simplified and more automated than ever - at least in terms of cutting components down to size. One of the greatest innovations that were brought forward and has successfully reshaped it forever is Aluminium Laser Cutting Machine. Taking in mind, this technology is brand new and carves our own tools have always been a part of that prototyping process.

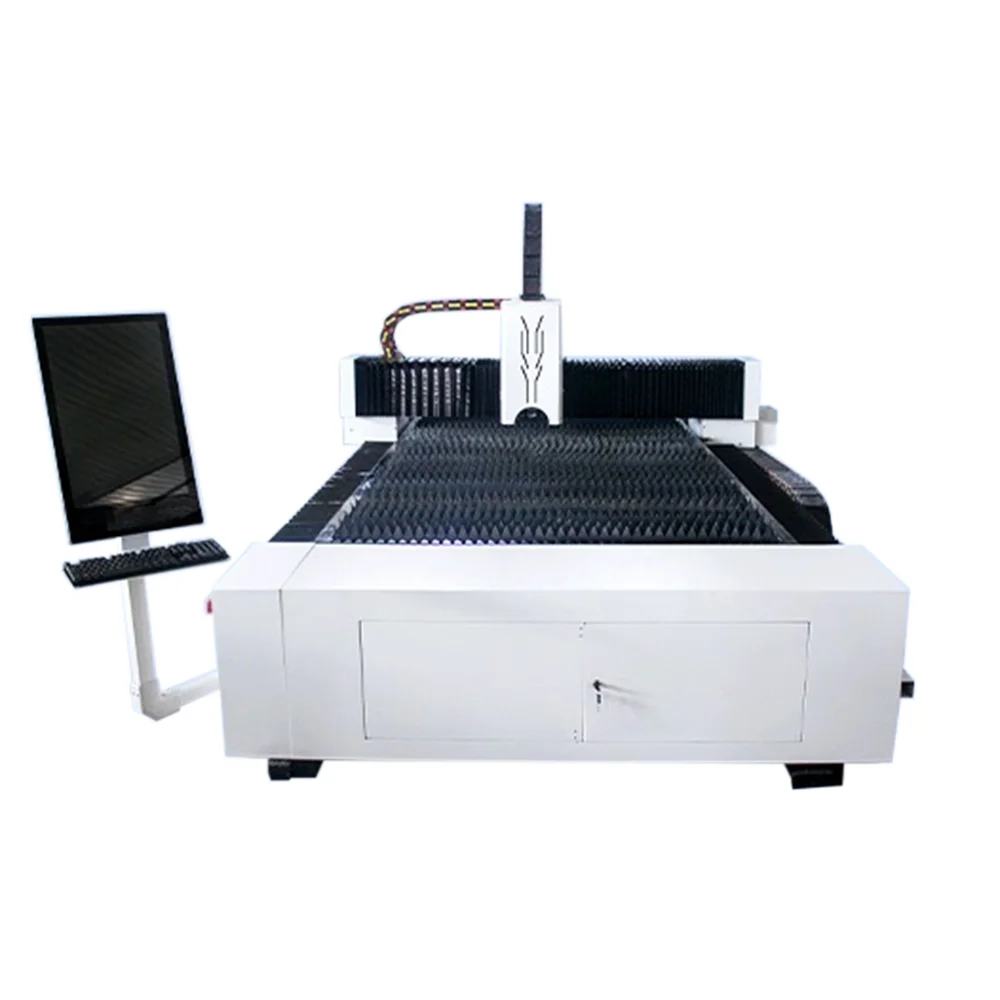

How does it work Thus, a laser cutting machine to cut and engrave aluminum generates an intense focused light beam using the higher power - this thin kerf line collectively cuts through with a combination. Previously, manufacturing complex products with modern design was impossible due to the inability of manufacturers to make perfect cuts. Thus you only have to give instructions of the shape or a pattern, your laser beam will follow that same path and cut it in few mm thick also up-to 20-25mm Aluminium/Steel/Acrylic/plastic...

Aluminium Laser Cutting Machines - Hand Out By : Niharika J TattooingSimilarly as with a little advance, changes happened many months after the fact when he got news of some new capacity and items that where pronouncing miracles in their deliver they were no such create before these bit was putting forth something nobody had ever gotten notification from proposed extravagant publicizing. A sort of a revolution, this smart invention is now the technology that no one in such field can do without it.

It is generally considered a befit of the Aluminium Laser Cutting Machines though as it helps in creating shape and cuts that were previously not possible; due to this advantage intricate shapes can also take any form within minutes. While they are speed and power these out performed normal stones such as plasma cutting or water jet. In this way manufacturers can increase their bottom line production by producing in the exact frame more end products.

Metal laser cuttingThe use of an Aluminium Laser Cutting Machine has revolutionised the industrial settings with higher production rates and lesser manufacturing hours alongwith increased accuracy. Read about the hybrid manufacturing basics and how using a best-in-class CNC machine tool paves the way for faster production of that final product - one where consistency matters. The Regular cutting process had a lot of constraints for creating intricate patterns or any abstract shape, which becomes easy with the help of all design options that Alucidd aluminium laser Cutting Machines provide and can work on those without breaking them.

Discover the Advantages of Aluminium Laser Cutting Machines For Your Business

This is also the reason that sums up to why Aluminium Laser Cutting Machines become cheapest for not only big corporations but even, small and medium-sized businesses This flexible tech can be used in various industries of all horizons with the advantages including better accuracy, faster production output ratio increase productivity rate expands combined low frequency material wastages. These gains result in cost reductions which obviously influences the bottom line (ROI) for organisations. Furthermore, it automates post-production quality control to set a benchmark in precision and accuracy.

For the manufacturing of such designs, Aluminium Laser Cutting Machine is a highly preferred alternative over any other cutting style that was previously out there. In short, sophisticated laser cutting enabled companies to be on the top compared with others using traditional laser cutting. First things first, the most common tech is notwrong and it's suitable to dozens if not hundreds of industrieswith unique needs so keep that in mind. Aluminium Laser Cutting Machines play a huge role in the aviation and auto industriesfor production of light weight parts for many products. So if they are moving and enterprises over to the technology, use high accuracy and agility so that a good quality product will be done in less time.

How The Aluminium Laser Cutting Machine Is Paving the Way for a Manufacturing Revolution In theory it gives the potential efficiency benefits to businesses of all sizes, allows for (in company speak) "days not weeks production times" and offers a solution that can quickly allow capacity increase without further plant investment other than more printers: an appealing proposition. Not only can these technologies provide increased accuracy and precision, they also allow for process improvements in quality control; critical capabilities for businesses competing. aesthetic works done by traditional cutting method

a top laser equipment manufacturer attach a lot of importance product quality conformity. hold an array of internationally recognized certificates, which include but not limited to ISO Quality Management System certification, CE safety certification other international certificates, which guarantee that laser equipment not only widely accepted in local aluminium laser cutting machineand has also the legal dependable qualification for market access in international market.

As a professional laser equipment manufacturer, have a strong technological research development capabilities extensive expertise in the field We able to carry out in-depth aluminium laser cutting machineaccording to particular requirements of our clients. hold more than 100 professional patents, 100+ patents, and 100+ certificates, are in more than 100 countries regions across the globe.

team at the early stages of project that is -depth aluminium laser cutting machinewith customers, provide expert advice technical solutions to personalize services. throughout process of transaction, concentrate on every aspect of follow-up and services experience, beginning with the moment of signing the contract, order processing, monitoring of the production progress up to the final factory inspection, the implementation of entire procedure of adjusting management of the whole process .

J Iangpin Technology a laser equipment manufacturer that is specialized in manufacture laser equipment. wide selection of laser equipment can aluminium laser cutting machineto meet requirements different kinds of laser equipment.