Reveal More into the Universe of The Laser Cutting Machine for Amazing Work!

Do you have a passionate personality with the ability to create innovative and engaging work? If you are a DIYer and love to surprise your friends, teachers, or family with what you create -you have come to the right place!

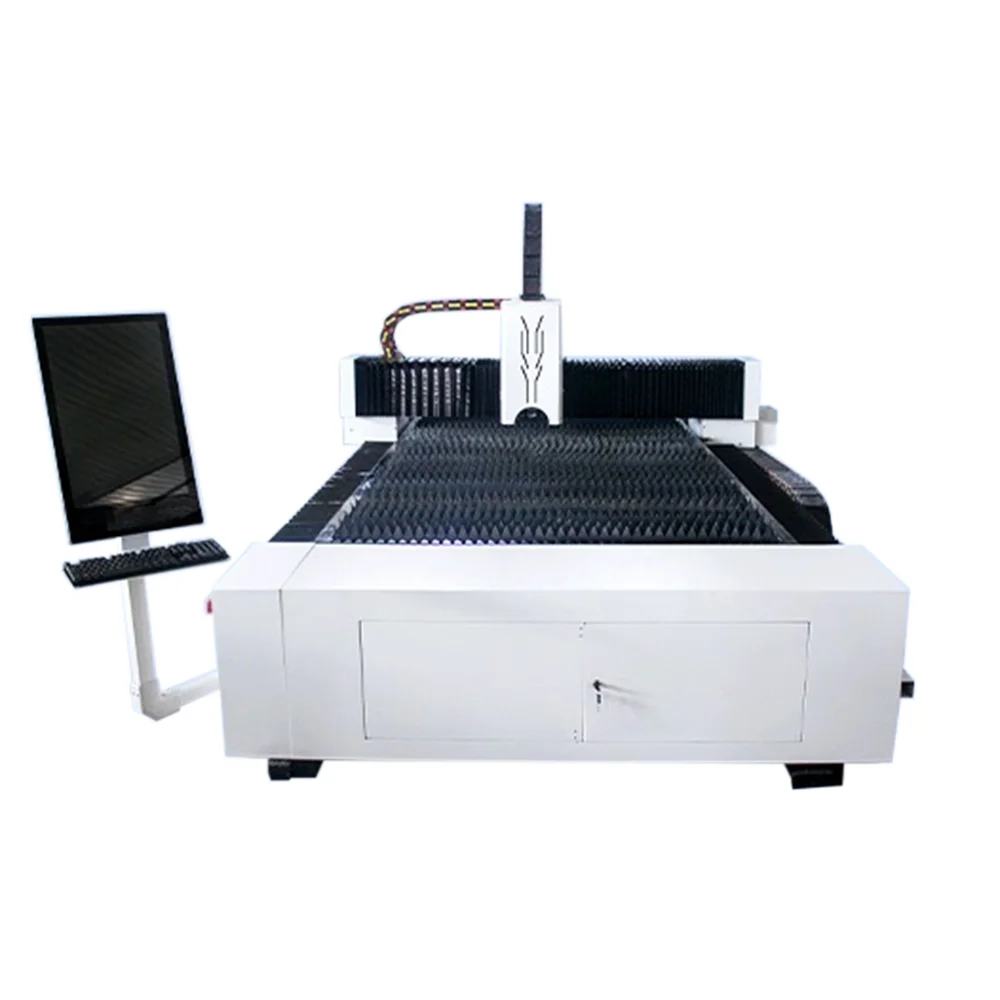

That is why laser cutting machines lead the way in terms of these advancements, and present advantages that can make your projects more innovative than ever before. In the following thorough review, we will cover: The benefits of laser cutting machines How do they work Safety Quality Applications And more!

Laser cutting machines are highly efficient when it comes to the precision processing of complicated patterns, be they wooden or plastic-metal hybrid. The following list investigates a little bit more about what makes them so advantageous.

Accuracy and Precision: Laser cutting provides precise, crisp cuts with pinpoint accuracy, making it possible to produce the most intricate designs effortlessly.

Speed and Efficiency - Since these machines operate at much higher speeds in comparison to performing machine shop work by hand, they speed up the completion of your projects meaning that there will be only a minimal amount time waiting between production cycles.

Access to Several Design and Material-Making Options: Bringing a laser cutting machine on board means you are open to experimenting with multiple designs and materials, taking your creative spirit off the leash.

Laser cutting machines are powered by modern technology and have many features along with an array of advanced capabilities. A few examples of these radical features include:

Auto Material Thickness Detection: This feature is so far the most unique one, and it ensures perfect alignment minus over-cutting as well under cutting.

Red dot positioning: The instructions for precise cutting will improve the precision of processing and reduce waste.

Fast Scanning: This feature makes sure that images can be scanned to a computer program without any hitch so as soon the cutting process is done, it will easily pass through just in no time.

Safety features are critically important to the operation of laser cutting machines in that their implementation guarantees a safe working space for operators. Key safety measures include:

Protective Eyewear: Operators should be using glasses or goggles, that are specialized for this work, even shields to protect their eyes during the operation

Panic Button: If things don't go as planned, the machine has panic buttons able to switch off every single motor (photo at Test Stand for illustration).

Housing and Blast Deflectors: Offering heat defense for those in the operating cell, overall safety is increased.

The main principle to implementing an etching with a laser cutting machine is quite simple, uses only 3 steps. It is probably the most comprehensive guide on how to get your machine working for you, not against.

Design in a Computer Program: Start by making your design on any computer software.

Material and Machine setup: get your materials ready and dial in the machine settings so you know laser power, speed, focus.

Process the Design : Send your design or image file to be cut by the machine.

Materials Alignment: Make sure material placement in the machine is aligned before starting with the cutting process.

Monitoring the Cutting Process. You can watch as our machine carves out your design one bit at a time.

As leading manufacturer laser best laser cutting machine, attach great importance to product quality compliance. have a series of international authoritative certifications, including but not limited to ISO quality management system certification, CE safety certification other international certificates, which ensure that our laser equipment not just widely acknowledged within domestic market, but also has legal dependable qualification to access global market.

J Iangpin Technology a top laser equipment maker covers an area of 2,156 square meters. have five product lines best laser cutting machinea wide range product models, addition to a wide range accessories fully satisfy customers' needs. Specialized in laser manufacturing, offer a vast array of lasers to satisfy the requirements a variety of laser equipment.

concentrate on entire process transaction starting with signing of contract, through best laser cutting machineorders monitoring production progress.

are a leading manufacturer laser equipment with a robust research best laser cutting machinedepartment, with wealth of knowledge in field. We can customize our products to meet demands of each customer. have 100+ professional patents, 100+ patents, plus 100+ certificates, are in more than 100 countries and regions throughout the world.

If you are buying a laser cutting machine, the best service should be on your top preference and high specification. As long as the customer is there, technical and heavy machinery can also take reliable support with its dating. A premium-grade machine is guaranteed for a duration during which you can get issues, should they happen to occur within that coverage analysis period.

Leveraging a Range of Uses for Laser Cutting Machines

Laser cutting machines are so versatile they can be used for a whole range of applications. Here are some examples of how these machines could be applied:

Acrylic Cutting: Perfect for sharp signage, awards, boxes or displays.

Cutting Wood: If you wish to carve a wood toy, puzzle piece, or figure small parts and tiny details are required.

Metal Cutting Industrial applications that require precise cutting of the materials.