Demystifying The World Of CNC Laser Cutting Machines For Metals

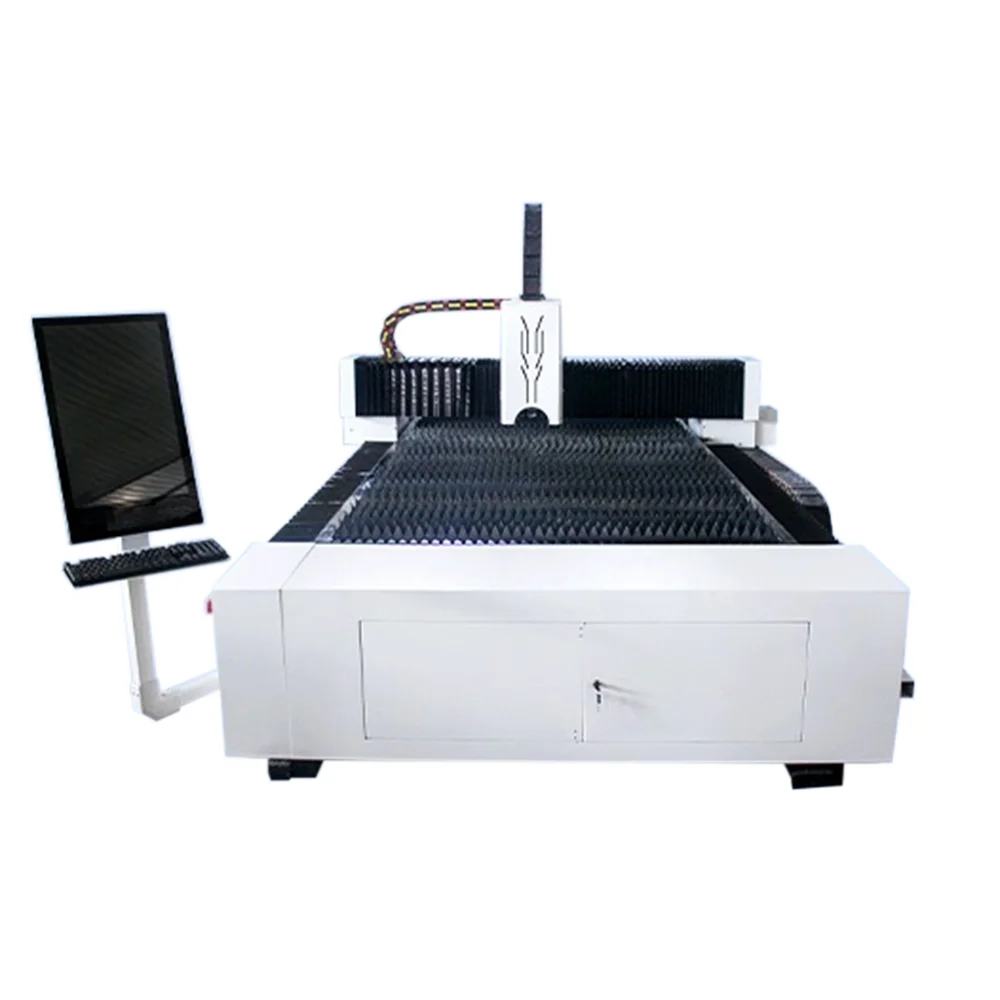

An introduction to CNC Laser Cutting Machines A laser cutting machine is an impressive bit of kit, and it is used to cut all sorts of metals from stainless steel through to aluminium. Because of the different advantages it may give, these revolutionary machinery are being put into practice by a number of industries. In this blog, we have briefly explained everything related to CNC laser cutting machines.

The Pros of CNC Laser Cutting Machines

CNC laser cutting machines offer a wide selection of benefits like cost-effectiveness, time-efficiency and stitches quality. A CNC laser cutter has the capacity to cut virtually every type of metal imaginable with unbeatable precision, producing cuts far superior in quality compared to traditional methods of cutting. In addition, the CNC laser cutting machine itself is equipped with technology that has simplified the process of coarse breaking and greatly reduced labor intensity and production costs. Such increased efficiency can help a business get things done in less time, thereby saving money and increasing competitiveness.

The plateau in which conventional cutting methods have overpowered all the years is now seeing a new wave of innovation from the CNC laser cutting machines. These machines function using various adaptations; a few models use nitrogen to adjust the edge of completion on the metal being cleaved. This edge coating is a critical feature for maintaining the natural properties of metal and keeping it strong and functional through every phase fo fabrication.

Laser cutting machines are very safe to work with and laser cutters have strict safety protocols in place while operating the cutter machine for carrying over industry regulations. These machines come with safety features such as protective eyewear and guards, and they are built to work only when the operator follows certain guidance from the manufacturer. The CNC laser cutting machine is beyond standby at the top when it comes to safety - these machines ensure user security, uphold environmental protection and takes care of themselves.

CNC laser cutting machineIt is very user-friendly to use and drill various holes with specification on the product, as operators can follow the online tutorials or manuals effectively. Operation of these machines is a pretty easy : just put the data in software and machine do all this automatically. What's more, the machines can be programmed to make highly accurate cuts defined by the software and operators can start a cut cycle then leave them alone so they work on something else while it operates.

Regular upkeep will work to preserve the high quality output of CNC laser cutting machines. Manufactures usually provide servicing for these machines to make them work as efficiently. Preventive maintenance reduces the need for expensive repairs, and also ensure tasks are carried out on time and with accuracy thereby improving overall operational efficiency.

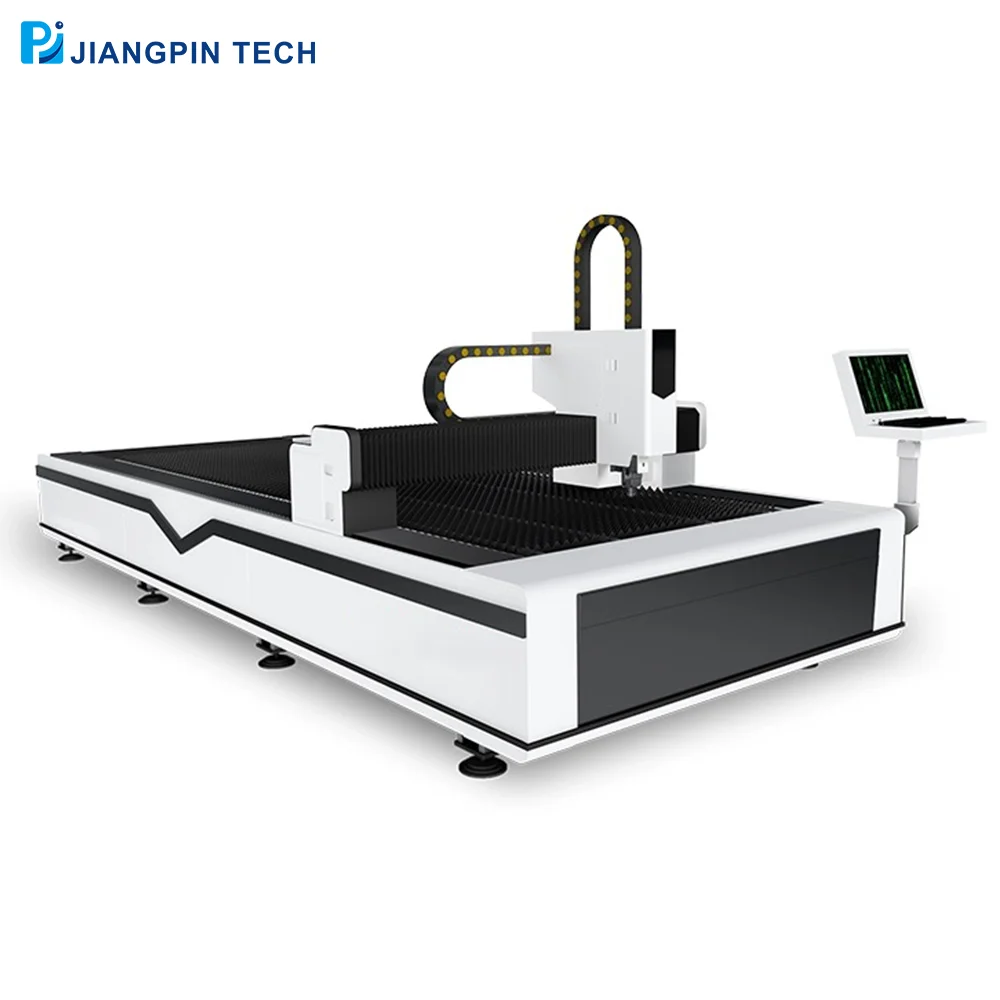

As top laser equipment manufacturer, attach great importance product quality and conformity, hold numerous international authoritative certifications, such as but not only ISO quality management system certification, CE safety certification other international certifications, which assure our laser equipment isn't just recognized in domestic market, but also has the legal compliant certification for market access the cnc laser cutting machine for metalmarket.

focus on the entire process transaction from signing contract ordering processing cnc laser cutting machine for metalmanufacturing progress.

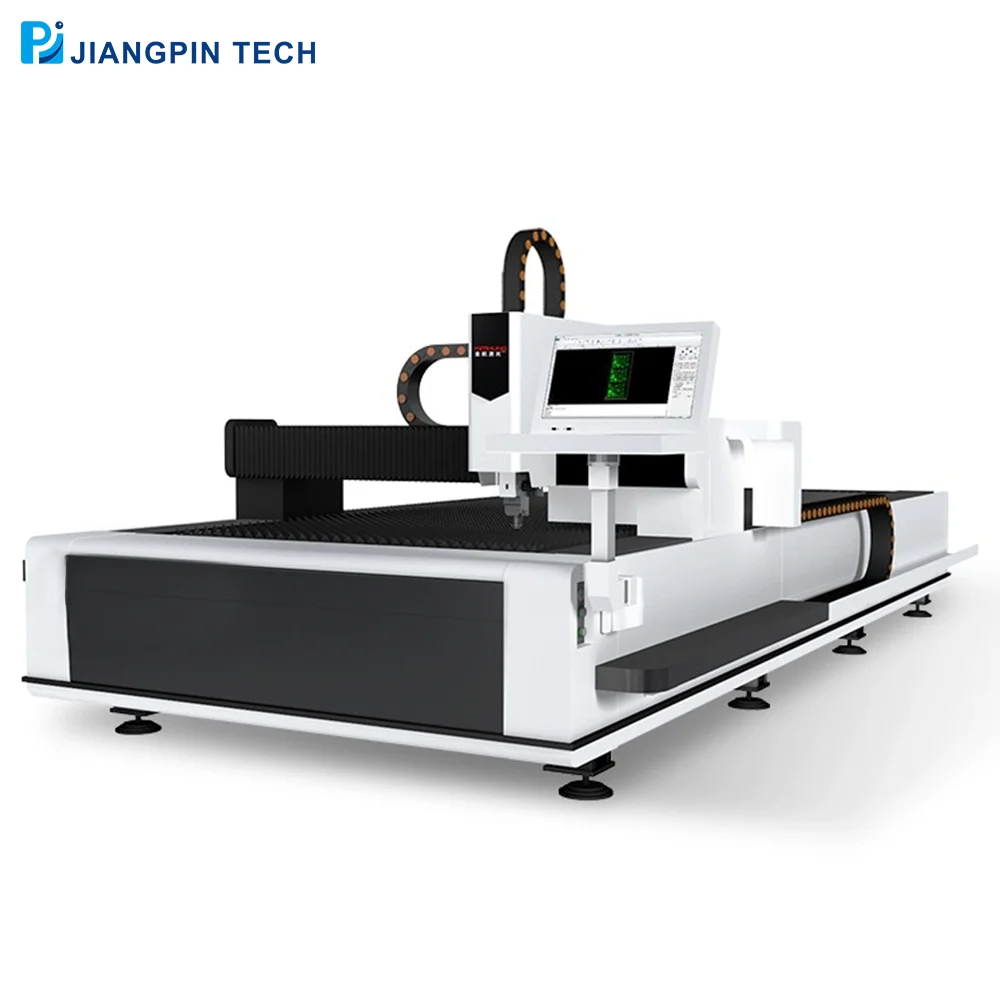

J Iangpin technology a reputable laser equipment maker that covers 2156 square meters. It has five product lines, which include vast range of cnc laser cutting machine for metalmodels, along a myriad of accessories satisfy clients' demands. Specialized laser production, company offers large array lasers satisfy the requirements of a range of laser equipment.

are a leading manufacturer laser equipment with a robust research cnc laser cutting machine for metaldepartment, with wealth of knowledge in field. We can customize our products to meet demands of each customer. have 100+ professional patents, 100+ patents, plus 100+ certificates, are in more than 100 countries and regions throughout the world.

The ability for CNC laser cutting machines to offer precision and accuracy has completely changed the metal cutting game, all while giving their users a massive production quality boost. These machines can be utilized removing the mistakes that many forget in manual cut methods or using traditional equipment, as they are. reduces human error and gives very better precision cutting fashion is set by this process of automated cutting machine. The in-depth nature of each cut, made possible by CNC laser cutting machines accompanied with the level to which their specialists take action towards accurate results over and beyond just again supporting a conclusion.

Various Uses of CNC Laser Manufacturers

CNC laser cutting machines have high applications in many industries because of the broadness on which they are used. These metal cutting machines are equipped to cut a variety of materials in myriad thickness levels such as steel, aluminum, brass and whatnot! Thus, sectors like automobile, construction, signage industry aerospace and the likes have been utilizing a CNC laser cutting machine to deliver sharp as well as complex cuts on their metal parts. The adaptability of such machines in different industries speaks volume, and is synonymous to how critical it has become for businesses to better their operational efficiency at all costs.