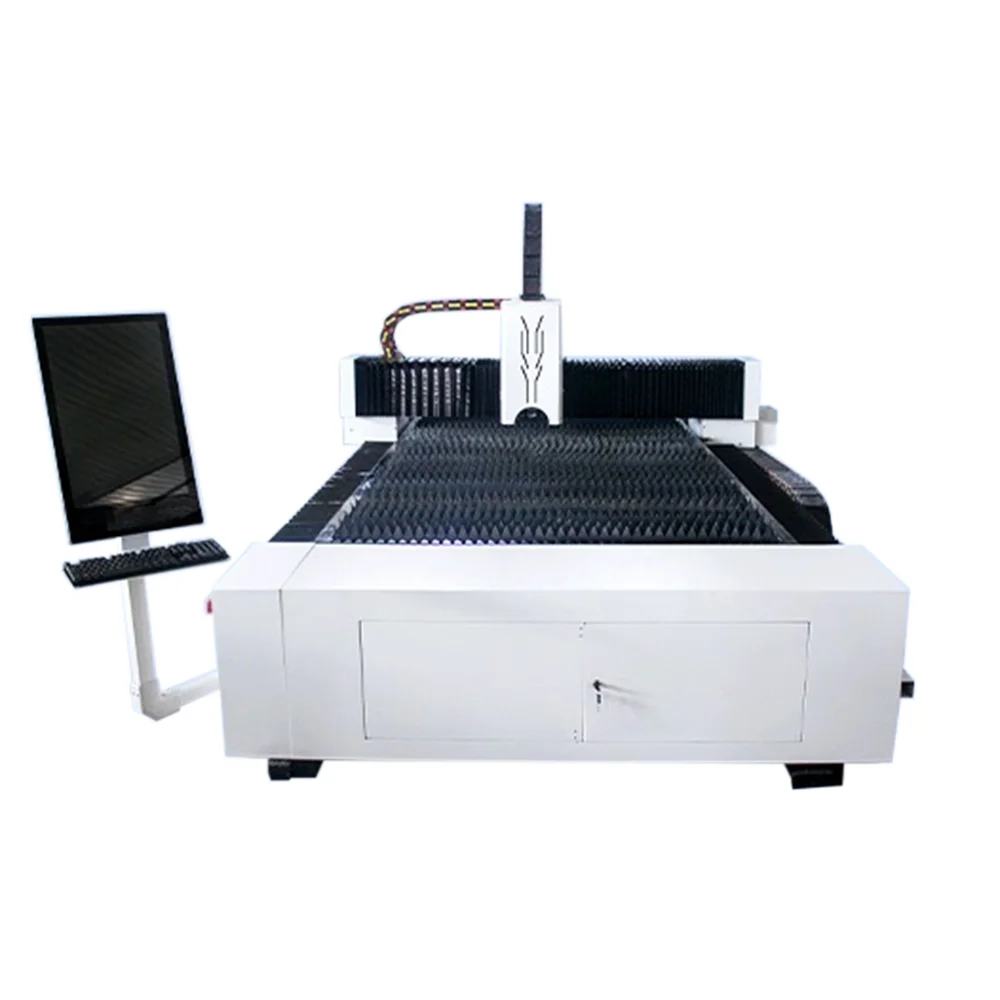

Published on An Introduction to a CNC Laser Tube Cutting Machine Are you in need of a tool that will help you cut metals and tubes with accuracy using high-speed processes? If you are someone into tube cutting services in Mumbai, let me tell you the answer to your need might be The CNC Laser Tube Cutting Machine! This updated tool utilizes advanced technology to simplify your cutting processes, we are going here too explore the benefits, innovation, safety, operation how it works & operate service of CNC Laser Tube Cutting Machines.

CNC laser tube cutting machines are very versatile and can offer high throughputs. These machines can also cut a variety of materials - ranging from aluminum, brass, copper to stainless steel and carbon; with each having its own distinct cutting capacity. These machines are quick and agile which means you can get through your projects faster, with less clean up. The machine has a high-productivity volume since, it generates the same form of fabrication without any human physical power.

CNC Laser Tube Cutting Machine has changed the face of metal and tube cutting industry. Most of the new models are smaller with the features such as automatic loading and unloading that makes it easier to produce large amounts of cut tubes fast. These machines use very sophisticated software for machining as well - to make parts with intricate geometries is trivial when using that kind of equipment.

First, the user safety of operating a CNC Laser Tube Cutting Machine is far superior. These machines had been created to be extremely safe. It is designed with safety-critical elements, and the computer control system of the machine will not allow operation if any one of its safety features fails to function properly. In addition, the work piece itself is never in danger because it is carried through a fixed path and thus can not collide with other tools or parts of the machine.

The CNC laser tube cutting machine is so simple to use. To start cutting, just load your design into the computer program of the machine. The next one is to secure your material and start the machine. So, let the CNC Laser Tube Cutting Machine manage you! You will be able to monitor the whole progress even on your computer screen.

team in beginning stages of cnc laser tube cutting machinethat is in-depth communication with clients, providing expert advice technical solutions to personalize services. during transaction process pay attention every step of the follow-up and service experience, starting with the moment of signing the contract process, processing of orders, monitoring the progress of production up to final factory inspection, and the execution of entire process of adjusting the management of the whole procedure .

are a leading manufacturer laser cnc laser tube cutting machinewith robust research development team, as well as wealth of expertise in field. We can customize products to meet the specific requirements every customer. hold more than 100 professional patents, 100+ patents, and 100+ certificates, and service more than 100 countries regions across the globe.

J Iangpin Technology a laser equipment manufacturer that focused on manufacturing laser equipment. wide variety laser equipment can easily cnc laser tube cutting machinemeet demands different laser equipment.

We a top manufacturer laser equipment. is why we put a lot emphasis on quality of our product its compliance. laser equipment we offer backed by several internationally recognized cnc laser tube cutting machineincluding ISO QMS certifications, CE safety certificates other international certifications. These certificates ensure that laser equipment a popular choice in the domestic market but also qualifies the global market.

The initial step in implementing a CNC Laser Tube Cutting Machine is to develop your component using an computer-aided design (CAD) program. After you finish with the design of your part, all that is left to do for a preliminary stage is uploading it into this CNC Laser Tube Cutting Machine software. Secondly, you will have to get your content ready. Cleaning would be done and burrs ought to be eradicated before the edges that were pounded should smoothed. It is at that point, you need to fix your material into the machine. After that, you can begin the work by activating your machine.

CNC Laser Pipe Cutting Machine Quality and Service

The Vtop CNC Laser Tube Cutting Machine delivers a high-quality machine specifically designed and built to meet the needs of manufacturers. They are also trained from the ground up, with comprehensive training and support so that their customers know how to properly operate and maintain their machines. We are also providing technically good after sales service to make sure the best performance of your machine from best CNC Laser Tube Cutting Machine supplier.

The Application of CNC Laser Pipe Cutting Machine

A variety of industries make use of CNC Laser Tube Cutting Machines. Furniture Pipe fittings Sanitation products Automotive parts Construction materials etcorestaurants pubs shops hostels tourism gates factories car sheds Warehousing any many other common uses. These devices are also used by businesses engaged in building unique and custom pieces as well.