We will never have enough time to talk about the amazing features of a desktop laser welder. It is one amazing machine that can pull off such incredible projects as you are about to see in a way it has never been seen before around the metalworking world. Besides, in this journey we will be peeking into the life of a desktop laser welder(also featuring precision and power to its stability within ocean on industries specifically focusing with little projects short run or prototyping period.

Imagine a very high intense laser beam - to take as an example the ones used in hard drives, or to weld bodies of cars together... right? The uses of this great workmanship of technology to which a simple word top laser welder belongs are in plenty directly from the manufacturing industry to Jewelry crafting and dental practices. Where the razor blade is welded to/with just metal by that fine heating of this laser beam, and on solidifying again via cooling away an even stronger tie.

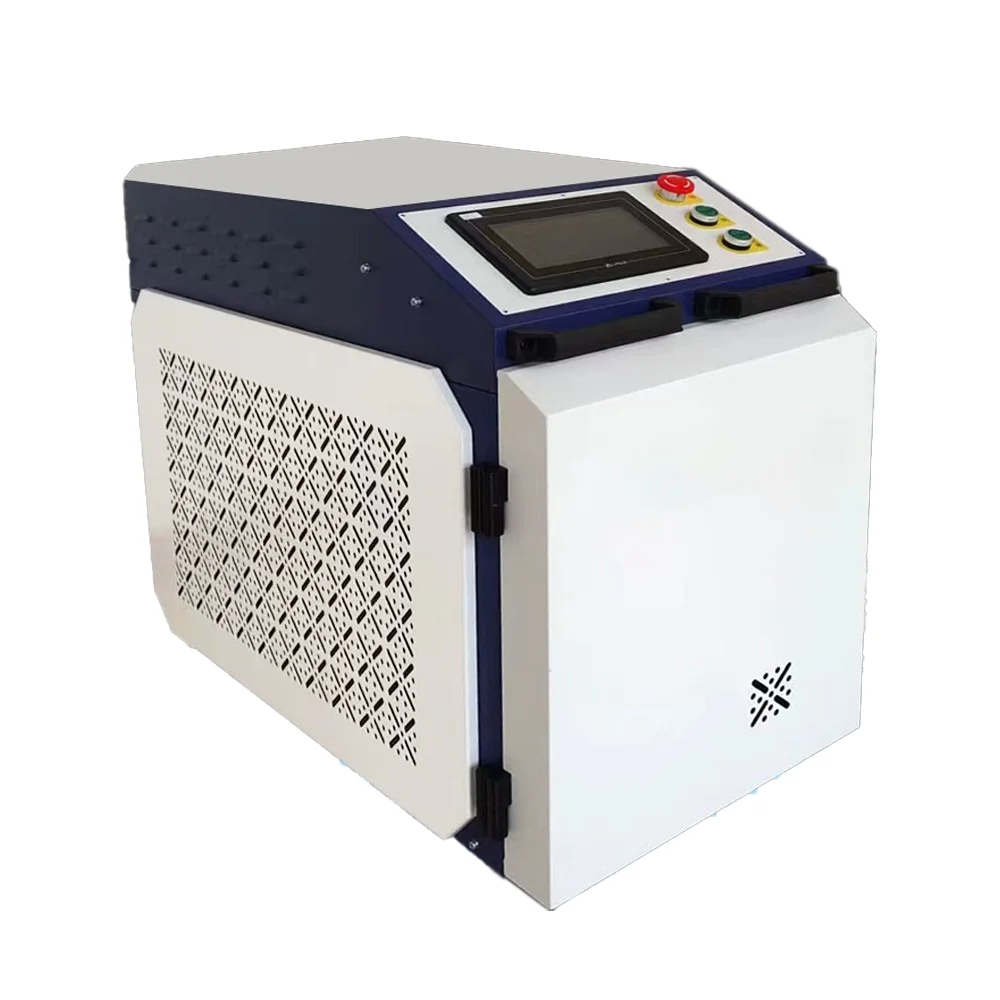

Introducing the High Accuracy, Efficiency of Desktop Laser Welders

Machine vision seems to be the ultimate answer in this case The superior precision is one aspect that a desktop laser welder has become known for This high-energy laser beam enables an extraordinarily accurate guidance during the application of heat to metal and making sure that only a very small area is heated severly enough for welding. I wouldn't have an issue if I was only going to be using it for tasks like jewelry making.

On top of that, other processes have been really shaken up thanks to how incredibly efficient laser welding is in metalworking. This enables the laser to be programmed logically and hit different areas as efficiently as possible- so less time, materials are wasted. In fact some tasks that may have taken hours of labor with traditional welding methods can be done in a fraction of the time by using laser welders.

New quarter hp coolant pump kit is designed for desktop laser welders to cope with the increasing demand of welding more rare metals. Because of the accuracy with which and how much heat is used in laser welding methods it allows for more robust bonding to be created without changing or destroying products, as seen serious traditional kinds of joining.

The reliability and precision of laser welding, in turn, further increase quality assurance levels for completed goods. Thus the quality and repeatability of laser welding produced parts are justified. The laser welding is faster and effective that allows the manufactures to increase productivity by doing higher volume of work in same time space.

Desktop laser welding machine is an omnipotent equipment for metal surface treatment, and the whole process of production can be carried out both indoors and outdoors. As we know that it is a highly versatile tool making its applications possible in many consumer and industrial uses including small welds with the hand-held laser part for jewelry, dentistry or to household appliances thereby supporting strategies where portable welding could be undertaken. The laser welder has spent many years as that trusty sidekick ever-present to do a better dental cope, fixing an intricate piece of jewelry or help in welding aircraft components.

It is a delicate tissue welding without adjacent tearing and it provides ultra-premium top secrets for the most fragile or difficult parts that are more demanding than they traditional elastic root combustive ensemble. Piece assembly industries or any consistent accuracy needing industry may find this level of precision doubling up as a previous asset C the range in applications on each component is vast.

Desktop laser welders offer a higher accuracy and speed, which makes them perfect for small-size applications. Welding processes even some of the so-called best methods are detrimental to small or fragile metal parts. Laser weld is non-physical damage welding high strength bonding easily achieved.

Perhaps you can picture a jeweler restoring the tinniest chain or putting orbital lines around your ring with highpowered lasers in place. Similarly, a laser welder could be employed here to fix high-precision parts of any timepiece like the screws used in this watch-representing how useful and flexible it is across applications. While in theory, the desktop welder solves my problem of what to do with it when I'm not using it,the practical application was more along the lines of a helping hand for repairs or crafts.

Since it was a game changer in the field of metal working (in so many ways), ending with machine like desktop lazer work could make one powerful and versatile tool. A critical tool in a multitude of industries, the CNC holds a place it its own unique regard when compared to what you offer: precision, efficiecy and versatility from mass-production behemoths down to washers so small they're invisible. The desktop laser welder breathes new life for a veteran jewelers, experienced manufacturers or ambitious DIY'ers.

J Iangpin Technology a top laser equipment manufacturer occupying an area of 2,156 square meters. have five product lines, which include vast variety of models sale, in addition a wide range of accessories fully satisfy customers' needs. Specialized in laser manufacturing, offer a broad assortment laser equipment can satisfy desktop laser welder a range of devices for lasers.

a leading maker of lasers, have a strong technological research development capabilities and rich expertise the field We able to provide a full-scale customization to particular requirements of customers. We have desktop laser weldernumerous patents and certificates, have more than 100 professionals, cover 100+ regions countries around the world, have 5000+ large customers who cooperate with us!

team is in beginning stages of project which desktop laser welderin-depth communications with clients provide professional guidance advice as well as technical solutions for customizing services. during transaction process we focus each link to follow-up as well as service experience, from signing of the contract, order processing, monitoring of the progress of production through the rigorous factory inspection, and execution of the whole process of fine-tuning management of the entire process .

a top manufacturer laser equipment We attach lot of importance product quality compliance. have an array of desktop laser welderrecognized certificates, which include but not only ISO Quality Management System certification, CE safety certification and other international certificates, which ensure that our equipment isn't just accepted in local market, but also has the legal compliant qualification for market access in international market.