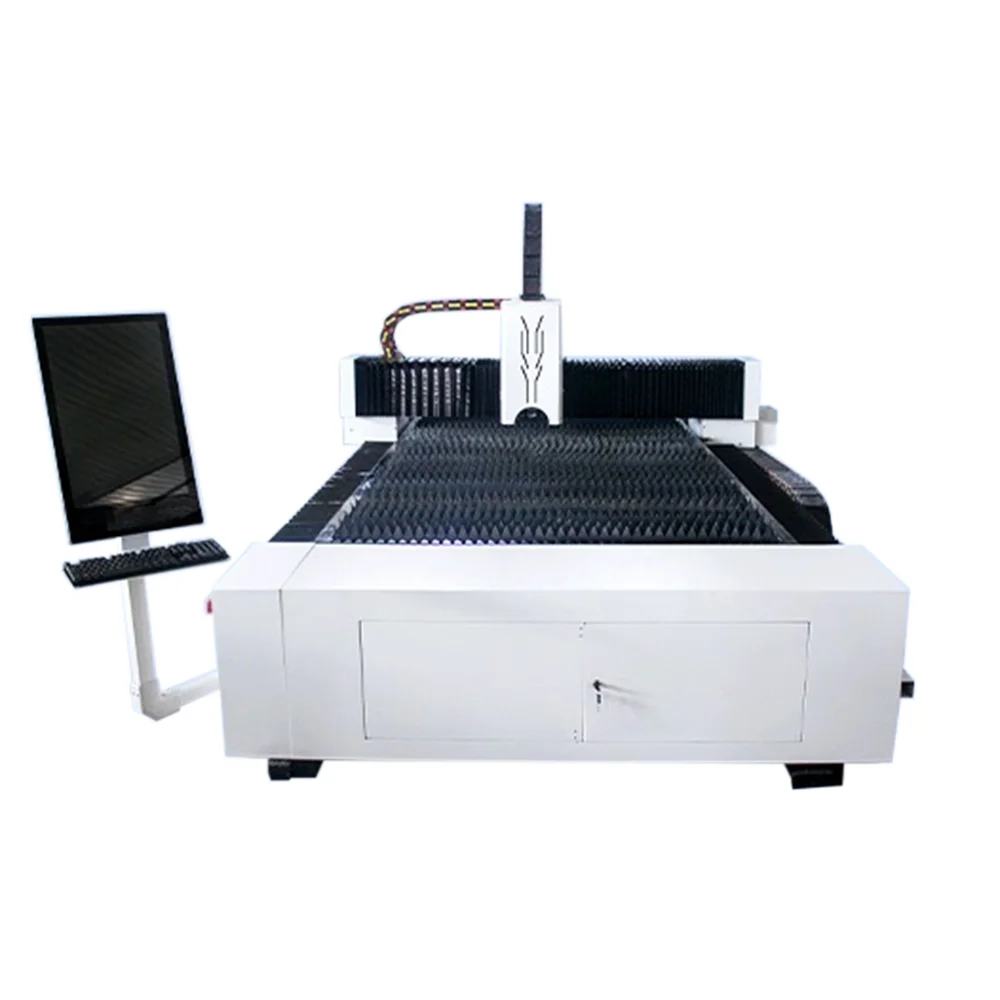

5 Great Advantages Of Using A Fiber Laser Tube Cutting Machine

The fiber laser tube cutting machine is very useful in a lot of industrial fields with its superior accuracy and speed while doing cuts on some kinds of materials. These machines are manufactured to mill out delicate shapes and designs on several materials like brass, steel as well as aluminum. Keep reading to explore the 10 benefits when using a fiber laser tube cutting machine:

One of the key highlights provided by a fiber laser tube cutting machine is its precision and accuracy. With their state-of-the-art laser technology, they cut through various materials with pinpoint accuracy. The impeccable level of precision that comes with it guarantees fine cuttings which can free you from the post-cutting work in most cases.

The first thing is that the speed of fiber laser tube cutting machine processing is very fast, and the cutting efficiency exceeds other traditional way. Not only does this allow manufacturers the luxury of producing at a quicker pace, it also means shorter turnaround times for companies. The ability to finish tasks more quickly means lower labor costs and higher overall productivity for the business.

This is maintenance work that we do not have to worry about with fiber laser tube cutting machines, unlike other type of cutting machinery. These machines do not suffer from wear and tear since they have no blades or any moving parts that require continuous replacement. This means lower care requirements, which in turn results in less down time for your production and smaller maintenance costs.

This ensures maximum material usage and minimal waste for Fiber laser tube cutting machines! Precise cutting technology allows them to cut just the right amount of material per part, minimizing use of materials.

Material Cutting Options (Flexibility)

These machines come with significantly more versatility and therefore the ability to cut through a variety of material types as well as thicknesses. It is best in cutting materials that are hard to cut such as stainless-steel, brass and copper due to its capability of material flexibility on laser machines for business.

Therefore, fiber laser tube cutting machines seem to be the cornerstone of industrial manufacturing processes because they outperform conventional plasma processing systems by providing better precision and efficiency. If companies have to purchase and add a fiber laser tube cutting machine, it is necessary for enterprises to consider issues like as production requisitions (capacity), financial problems(money) and the alternative reality in terms of constants related with the machines. As fiber laser tube cutting technology continues to evolve in the industrial manufacturing sector, we anticipate more developments which will present increased performance, efficiency and futuristic features.

J Iangpin Technology a manufacturer laser equipment which fiber laser tube cutting machinein production of laser equipment. wide range laser equipment can discovered to meet demands various types of laser equipment.

a top manufacturer of laser equipment, attach great importance product quality and conformity, hold an array internationally recognized certifications, fiber laser tube cutting machinebut limited to ISO Quality Management System certification, CE safety certification other international certificates. These guarantee that our laser equipment is not just acknowledged the market of own, but also has legal and compliant qualification for access to the international market.

are a leading manufacturer laser equipment with a robust research fiber laser tube cutting machinedepartment, with wealth of knowledge in field. We can customize our products to meet demands of each customer. have 100+ professional patents, 100+ patents, plus 100+ certificates, are in more than 100 countries and regions throughout the world.

team is in the initial stages of project which involves in-depth fiber laser tube cutting machinewith clients, providing professional guidance advice as well as technical solutions personalize services. throughout process of transaction, concentrate on every aspect follow-up and service experience starting from the date of signing contract as well as order processing process, through monitoring of the production progress, until the product's rigorous production inspection implementation of the whole procedure adjusting the management of the entire process .