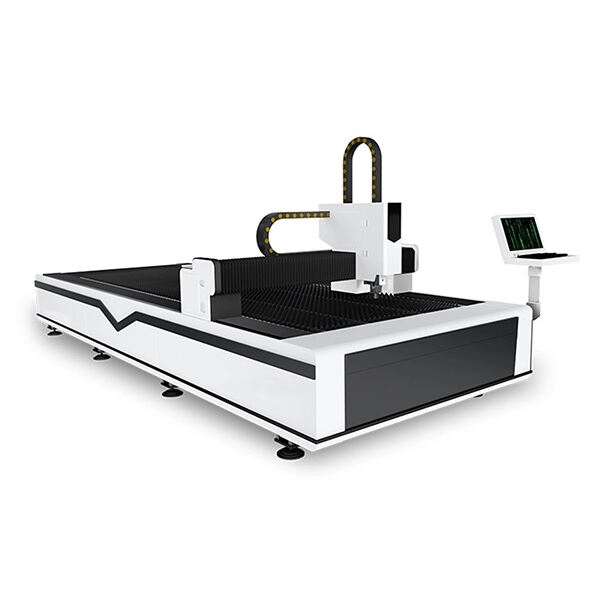

Modern advancements in the world of manufacturing have spawned new, high-tech tools that significantly improve both accuracy and productivity. A Jiangpin Technology fiber optic laser cutting machine is one of such breakthrough innovations. This is a breakthrough technology has changed the way materials are being cut during production. In addition, we will dive deeper into the many benefits of fiber optic laser cutter plans on how they work as well to know a wide variety of applications that it serves.

This is an astonishing evolvement represented between Jiangpin Technology fiber optic laser cutting machines when measured against conventional methods. These machines are known for being approximate. They are also able to make millimetre-perfect cuts around items with the use of high-intensity lasers. The fiber optic laser welder use laser beams to cut in lightning-fast speed rather than relying on the slower saw-based techniques of old. In addition, they lend their versatility to almost any material upon which the blades are bestowed be it metal, plastic or wood.

Their unique abilities to cut are due in part the modern technology that is used in fiber optic laser cutting machines. Because of this delicate art, these machines are able to deliver levels of precision that were never before available with conventional methods. They all do this using cutting-edge fiber optic technology to make sure the cut is of a good standard. This flexible nature - the fact that they can be programmed to transition seamlessly and at will between different materials is really unprecedented.

Safety In the Functioning and Use of Jiangpin Technology Fiber Optic Laser Cutting Machines

Safety procedures are a top priority when dealing with precision equipment like fiber optic laser cutting machines. You must also wear special protective clothing, masks and goggles which will protect you from the laser beams. Simply put, proper ventilation allows for the dissipation of harmful gases and fumes within a workspace so that they cannot accumulate. In addition, safety gear and a thorough knowledge of how to operate the optical fiber laser marking machine is required upon using them.

Although fiber optic laser cutting machines may seem simple to operate, they actually entail a series of minute steps. The operator starts by choosing the material to be cut, inputting this information into the cutting machine computer system. Therefore, the Laser Welding Machine cuts this material quickly and accurately. During the cutting process, it is essential for an operator to stay close and watch over the machine as this helps in delivering seamless high-end quality cuts.

Fiber optic laser cutting machines, like any other equipment need to be fitted with the best parts that will enable then maintain operational efficiency. Keeping these things in good condition through regular cleaning and maintaining is important to keep them operating efficiently. Moreover, successful cooling solutions must be in place to avoid overheating of the Metal Laser Cutting Machine and your hardware.

J Iangpin Technology a laser equipment manufacturer that focused on manufacturing laser equipment. wide variety laser equipment can easily fiber optic laser cutting machinemeet demands different laser equipment.

team in beginning stages of fiber optic laser cutting machinethat is in-depth communication with clients, providing expert advice technical solutions to personalize services. during transaction process pay attention every step of the follow-up and service experience, starting with the moment of signing the contract process, processing of orders, monitoring the progress of production up to final factory inspection, and the execution of entire process of adjusting the management of the whole procedure .

a leading maker of lasers, have a strong technological research development capabilities and rich expertise the field We able to provide a full-scale customization to particular requirements of customers. We have fiber optic laser cutting machinenumerous patents and certificates, have more than 100 professionals, cover 100+ regions countries around the world, have 5000+ large customers who cooperate with us!

a top laser equipment manufacturer attach a lot of importance product quality conformity. hold an array of internationally recognized certificates, which include but not limited to ISO Quality Management System certification, CE safety certification other international certificates, which guarantee that laser equipment not only widely accepted in local fiber optic laser cutting machineand has also the legal dependable qualification for market access in international market.