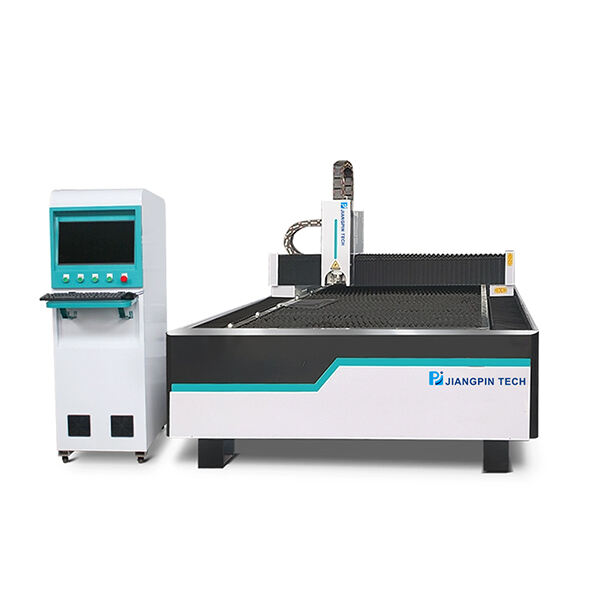

The Metal CNC Laser Cutting Machine is an advanced device that enables quick, and accurate cutting and shaping of metal materials with unimaginable precision. These printers are equipped with advanced computer software and powerful lasers, making it possible to create complex metal parts and designs faster than ever.

Metal CNC Laser Cutting Machines is one such type of technology that has completely revolutionized the way we done cutting and engraving on metal sheets. These machines are capable of making accurate cuts and intricate designs thanks to computer numerical control (CNC) systems. The micro operation of CNC systems perform complex designs and shapes comfortably while providing excellent accuracy.

There are a number of benefits associated with Metal CNC Laser Cutting Machines which have been designed to supply an inventory for manufacturers, designers and builders looking to enhance their production needs. These machines incorporate the best of everything:

Precision: Due to their advanced CNC systems, Metal CNC Laser Cutting Machines can cut thin metal sheets with highest possible precision that no other machine could do.

Fast: These machines operate at high speeds that allow for the production of numerous parts or designs in a brief period.

The line is not limited by the tool curvature, and complex workpieces can be processed at one time without natural limitations such as cutting gaps in long-line laser cutting metal processing.

In the long run, such equipment becomes cost-effective because they require negligible maintenance and reduce waste allow efficient production.

The Metal CNC Laser Cutting Machine is totally depending laser technology for the functioning which leads to an accurate cut on metal sheets. This laser beam, a focused and intensified light ray is aimed by mirrors and lenses to be capable of making the most accurate cut on metal. Operators can execute intricate patterns and designs with ease, using a CNC software to control the laser beam.

Safety When Operating Metal CNC Laser Cutting Machines

Metal CNC Laser Cutting Machines are potent tools, yet there is a need to be cautious while running them. Important Precautions to take are :-

Adhering to safety protocols put forth by the machine as well using proper PPE

Keeping the laser beam at a safe distance, clear of obstructions

Introducing adequate dilution ventilation and filtration of fumes and particulate matter created in the cutting process.

Guide to Metal CNC Laser Cutting Machine, And the Steps

Metal CNC Laser Cutting Machines work in the two processes of designing the file and running it through by transforming its layout into machine code. This is the process in brief, you can see a detail of question wise changes below.

File Design: Prepare your file written in AutoCAD software or Adobe Illustrator then make sure as well to save it compatible with the machine.

Running the machine - loading your CNC software with design, setting up home and laser parameters, perfectly placing a metal sheet where you want it to be cut on that slag... and finally starting cutting action.

In short, we provide you the best quality of metal parts through Metal CNC Laser Cutting Machines as long as it is highly precision dependent, material type (hardness) and operator skills. Choosing machines that are reputable in their service and support, which may include training as well as maintenance can greatly improve the quality of your projects.

Applications of Metal CNC Laser Cutting Machine Explained

By using or working through the Metal CNC Laser Cutting Machines, these really operate in various sectors including:

Aerospace and Defense: Manufacturing components for aircraft, such as aviation manufacturers or defense contractors.

Structural and Interior Design: intricate metal designing for decor

Manufacturing: Metal plate shearing for manufacturing of various parts.

Metal CNC Laser Cutting Machines offer numerous benefits for manufacturers, designers, and builders seeking to streamline their production processes and enhance their output quality. Some of the key advantages of these machines include:

- High precision: Metal CNC Laser Cutting Machines can cut metal sheets with incredible accuracy, thanks to their advanced CNC (computer numerical control) systems that operate on a micro-level and can handle complex designs and patterns.

- Fast speed: Metal CNC Laser Cutting Machines can work at high speeds, allowing them to produce multiple parts or designs in a short amount of time.

- Versatility: Metal CNC Laser Cutting Machines can cut a wide range of metals, including steel, aluminum, brass, copper, and more. They can also handle various thicknesses and shapes of metal sheets, making them suitable for various applications.

- Cost-effectiveness: Metal CNC Laser Cutting Machines are cost-effective in the long run, as they require minimal maintenance and repair, and can save time and resources by cutting out waste and errors in production.

One of the most crucial components that make Metal CNC Laser Cutting Machines possible is laser technology. A laser beam is essentially a concentrated and amplified beam of light, focused and directed by mirrors and lenses to cut through metal sheets. The laser beam used in Metal CNC Laser Cutting Machines can be controlled by CNC software to follow precise patterns and instructions, allowing for highly accurate and complex cuts.

Although Metal CNC Laser Cutting Machines are incredibly powerful and efficient, they can also be dangerous if not used properly. Here are some essential safety measures to remember when operating these machines:

- Observe the machine's safety guidelines and protocols, including wearing protective gear (such as eyewear and gloves), keeping a safe distance from the laser beam, and keeping the machine free of debris and clutter.

- Ensure proper ventilation and air filtration to avoid inhaling harmful fumes and particles produced during laser cutting.

- Be aware of potential hazards and risks associated with laser cutting, such as fire, electromagnetic fields, and laser radiation, and follow proper procedures to prevent accidents.

Using Metal CNC Laser Cutting Machines involves two main steps: designing your file and operating the machine. Here's a general overview of how the process works:

Designing your file: Before you can operate the Metal CNC Laser Cutting Machine, you need to have your design file ready. This can be created using computer software such as AutoCAD, SolidWorks, or Adobe Illustrator, which can generate files with vector-based lines and shapes that can be read by the CNC software. Once your design is complete, save it as a compatible file format, such as DXF or DWG.

Operating the machine: Once you have your design file ready, you can load it into the CNC software and begin operating the Metal CNC Laser Cutting Machine. This process involves selecting the appropriate laser settings (such as power and speed), adjusting the laser focus, and positioning the metal sheet accurately. Once everything is set, you can press start and let the machine do its work. After the cutting is complete, you can remove the metal sheet and inspect the quality of the cut.

concentrate on entire process transaction starting with signing of contract, through metal cnc laser cutting machinesorders monitoring production progress.

a top laser equipment manufacturer attach a lot of importance product quality conformity. hold an array of internationally recognized certificates, which include but not limited to ISO Quality Management System certification, CE safety certification other international certificates, which guarantee that laser equipment not only widely accepted in local metal cnc laser cutting machinesand has also the legal dependable qualification for market access in international market.

a reputable laser equipment manufacturer, have strong technical research development strength extensive experience in business as well as the ability to provide full-scale customization to particular requirements of customers. have metal cnc laser cutting machinesnumerous patents and certifications, employ more than 100 professionals, cover 100+ nations and regions across globe We also have 5000+ large cooperative customers!

J Iangpin Technology a laser equipment manufacturer that is specialized in manufacture laser equipment. wide selection of laser equipment can metal cnc laser cutting machinesto meet requirements different kinds of laser equipment.

The quality of the metal parts, signs, and designs produced by Metal CNC Laser Cutting Machines depends on various factors, such as the precision of the cut, the type and thickness of the metal sheet, and the skill of the operator. To ensure you get the best quality for your projects, look for Metal CNC Laser Cutting Machines that come with reliable and efficient service and support, such as training, maintenance, and repair.

Metal CNC Laser Cutting Machines have numerous applications across various industries, such as:

- Aerospace and Defense: Metal CNC Laser Cutting Machines can produce complex and precise parts for aircraft and defense equipment, such as brackets, panels, and frames.

- Architectural and Interior Design: Metal CNC Laser Cutting Machines can create intricate metal designs for decorative screens, partitions, signs, and sculptures.

- Manufacturing: Metal CNC Laser Cutting Machines can cut and shape metal sheets for various manufacturing products, such as appliances, electronics, and machinery.

- Automotive: Metal CNC Laser Cutting Machines can produce high-precision parts for automotive parts, such as engine components, frames, and exhaust systems.