Metal laser welding is a more acceptable new technology in metal connection techniques. Instead, this type of welding uses a machine that has been specifically designed to generate a high-powered beam that can be focused in such a way as to bond alloys where needed without the reliance on heat-based methods that are often found with conventional types.

Be Metal with Laser Welding Due to its numerous advantages over traditional metal fusion techniques, laser welding has become increasingly popular in recent years. The sophisticated system is able to deliver the highest quality welds with very little heat input into surrounding materials through a laser beam no larger than 0.002 inches in diameter, allowing for an optimized deep penetration welding mode and excellent control over energy deposition during welding operations.

Metal laser welding has one of the best things in low thermal distortion which produces smooth, uniform welds. This method is also less stressful on the materials being joined, promoting lower warpage and more defect-free finished products.

This gives a further possible advantage as metal laser welding is the ability to access tight areas using the small or hard-to-reach locations, in which case it may not have been feasible by traditional welding. This high precision to be conductive while welding has completely changed how the welds in future are going to look and significant reduce or remove grinding / post treatment process.

Metal laser welding Big What, the other end of it is a horizon to extend for using lasers to weld. Any application which needs to join thin or dissimilar materials - even thick gauges of metals, LOSP can provide a clean and quick joining method for the automotive as well as aerospace industries.

Metal laser welder, although easy to use requires preparation and strictly followed safety protocol. Prepare the welding site before work to ensure cleanliness. Adjust the machine according to the metal and required dressing up in safety Clothing before starting welding.

Incidentally high quality metal laser machine manufacturers will also offer perfect after-sales services or simply provide some warranty which ensures users can maintain and make the most of these devices. Devotes to customer help, the word above also provides on behalf of the firm stability germinate and quality output for metal laser welding machine.

So, that is also the reason why today I will discusses one of similar advanced on WELDING TECHNOLOGY, which high precision efficiency and safetyibilities unprecedented in history- metal laser welding technique. Laser welding of metals can employ the ability to assume original and eccentric welds, but always ensuring safety because of its superior quality.

Metal laser welder compares with old traditional welding way, the benefit is a lot. It allows much finer accuracy in welding, helping to avoid further grinding or surface finishing. Additionally, there is more freedom for welding as it can get into previously hard to reach areas in cramped spaces. It is possible because the laser beam can be manipulated and used to make finer, more precise welds. One more critical advantage of welding is that it offers lower thermal deformation with less material strain on the part being welded. As a result of this, there are fewer deformities and defects in the welding process making the welds seem way more even. Metal laser welding innovation has also expanded which hardware can be combined together. Due to the accuracy and low heat input of laser welding, highly volatile materials that have poor thermal conductivity across very thin or non-similar joints can be joined together in places where traditional processes are impossible. In addition to this, there are many benefits in the use of a metal laser welder over other types of welding. This capability allows it to weld with high precision, and reach ever harder spots. Help prevents the metal squashing out after welding. Laser welding might be one of the most well-discussed advanced processes in terms of being a better general alternative to other non-conventional techniques, at least for many metal applications. The resulting high grain density and strength of composite unitization give more grits per disc, translating into fewer rejects in finishing or grinding. This also creates reduced thermal distortion and stress on the welded material production a finer overall weld. Last but not the least, openings doors for welding different types of materials and materials that are thin to be welded together.

Metal laser welding is simple, but it can be a bit of prep and safety requirements. Keep the welding are clean before using machine Metal laser welders should be activated and the conditions for each material to work with set Enter the correct laser settings, including power level and pulse duration or frequency. Bring the laser towards the material to be welded, and remember your safety glasses or gloves as necessary. Wait for the metal to be cooled down and then you can touch or do anything else with it - we want to avoid both burns as well as damaging of ends in a fuse after welding. Read and obey the instructions of machine manufacturer. Careless welding can cause you to get hurt or your machine to be damaged. Prior to utilizing a metal laser welder, ensure the surrounding is clean and secured. Switch on the machine and set it up according to which type of metal you are welding. Put on work glasses and gloves, do not touch the metal while it is still hot after welding. Before using your silver welder, make sure the welding spot is clean with any debris removed. Power on the machine and adjust the relevant parameters according to material that you want to weld. Select the right laser parameters (power, pulse duration and frequency) Prepare protective glasses & gloves Take the laser and move it towards direction of material which is being welded (beware about safety measures do not touch this hot metal after welding).

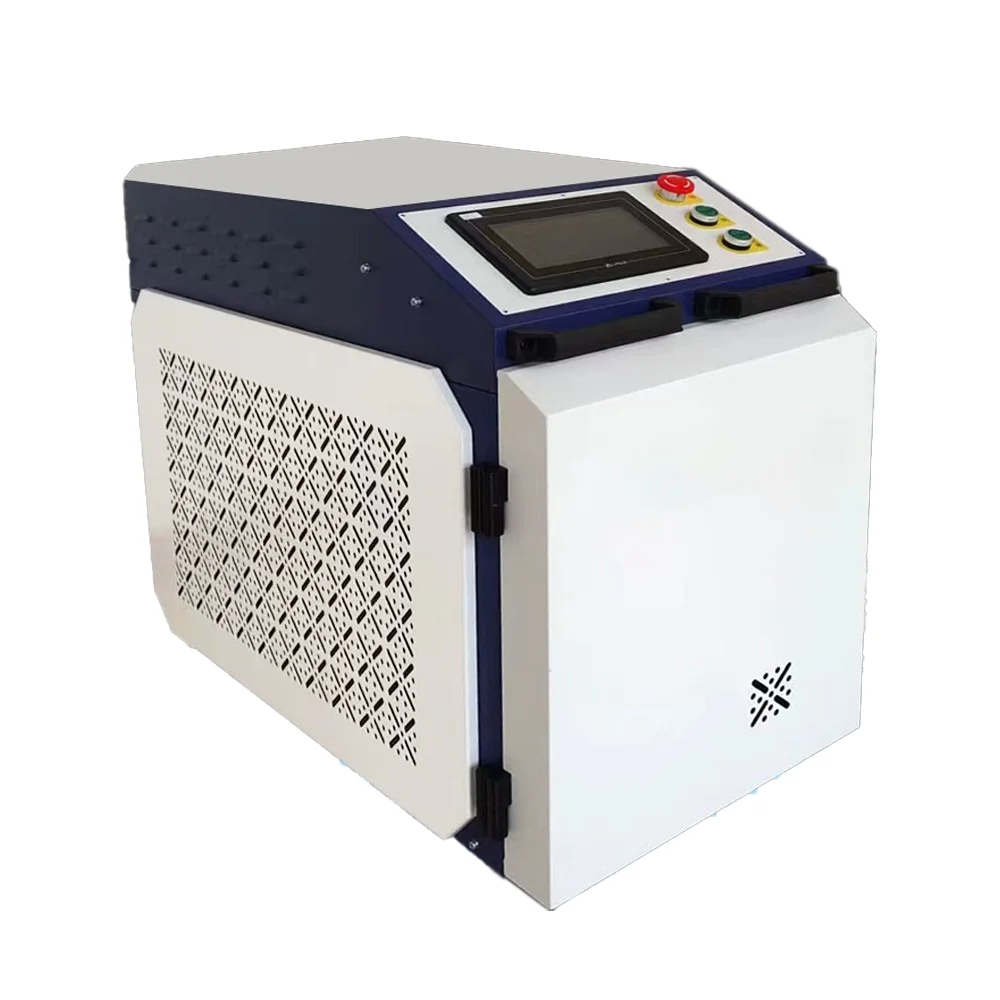

These are metal laser welders that made to the highest of quality and designed for a long life time. These are designed meticulously and with utmost care everything singly time to grant you the excellent paying consequences every single period. Metal laser welders also have good after-sales services, on top of their durable metal construction. They have staff of experts that help you with any question or problem during process (and provide customer service via mail, call and other supportive channels. If your metal laser welder seems to have a problem, please stop using it and contact the equipment manufacturer for assistance. They can work with you to optimize your tool and get the results that best suit your needs. Metal laser welders are built to last long. The manufacturer will help you if you have problems with your machine. Manufactured to exacting standards, Jensend has experience of building high-quality metal laser welders which are sure to last and perform at the pinnacle. The manufacturer's customer service teams can also give you real, expert assistance to utilize your machine better.

Applications of Metal Laser Welding: Automotive, aerospace and medical industries. This one is good for steel, copper and titanium joining as well as those on electronics etc. Bear in mind that when it comes to laser welding of metals, you are handling a dangerous process. You must wear the right clothes and some protective gear, glasses or gloves are a big one to stop injuries. Make sure the welding area is clear of any flammable materials, oils or solvents and anything that may burn during a weld. If you are not confident in how to responsibly weld with a metal laser, get insight from an expert before beginning any welding task. With a metal laser welder, you can use it to fix your child's favourite toy or build the next rocket. Always use protective shirt and make sure the area is fully safe before landing onto it as well. It is widely used in variousfields of metal laser welding, such as automobile manufacturing,aerospace and medical applications. You can use it to weld many different metals and materials, as well as for work on electronics. But keep in mind that if not done correctly welding can be a risky business. Always wear protective clothing and equipment like glasses, gloves wear should be done while welding area is free from some flammable substance or waste. If you are unsure of how to safety operate a metal laser welder, consult with an expert first before diving into your work.

As reputable laser equipment manufacturer, have a strong scientific research development extensive metal laser welderin the business can carry out in-depth customization according to needs of our customers. hold 100+ professional, 100+ patents, and 100+ certificates, are in over 100 countries and regions across the globe.

a top manufacturer laser equipment We attach lot of importance product quality compliance. have an array of metal laser welderrecognized certificates, which include but not only ISO Quality Management System certification, CE safety certification and other international certificates, which ensure that our equipment isn't just accepted in local market, but also has the legal compliant qualification for market access in international market.

J Iangpin Technology a manufacturer of laser equipment that specializes manufacturing laser equipment. wide variety laser equipment can easily found to suit the needs different metal laser welderlaser equipment.

focus on metal laser weldertransaction process from signing contract to processing orders monitoring the production progress.