Better Than Carbon SteelPipeline Laser Cutting Machines As A Resolution to Precision Metal Fabrication

Acting as a boon to multiple industries, alloy pipes are utilized in various forms due to their cost-effectiveness and lasting life. Since then, laser cutting technology has gained popularity as a way to create precisely cut metal pipes. This new type of application has offered the manufacturing sector a much cheaper, speedier and precise option to old school cutting.

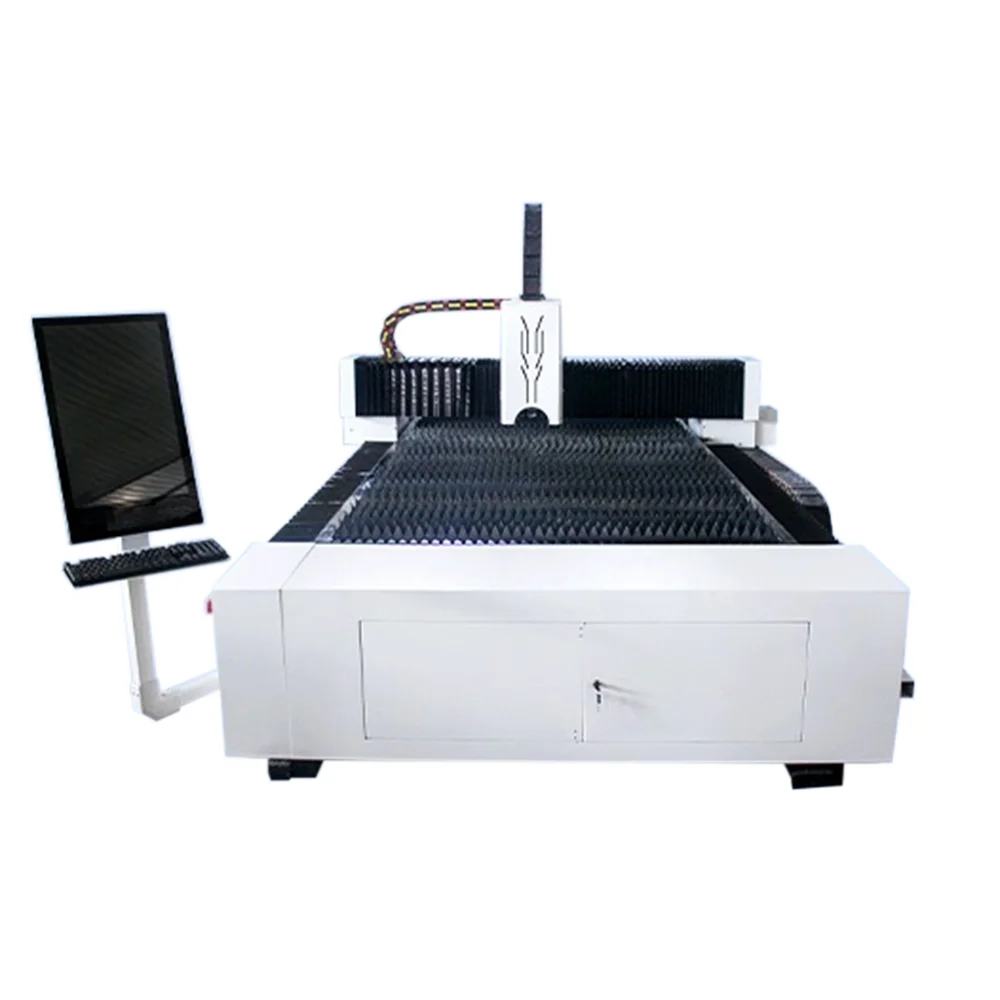

Laser cutting metal tube machines recently been a number of pretty amazing advances with technology, these also have effectively leapfrogged more than some steps altogether! Fundamentally, these are ultra-modern designer machines only design to provide best accuracy and stability in producing pipes. The latest models such as the Mazak Optiplex Fiber III, Amada FOM2RI 3015 and Bystronic Bystar Fiber are taking productivity to levels that were once thought impossible for modern metalworking by integrating fiber laser technology with automatic feed systems and three-axis cutting capabilities.

Metal pipe laser cutter is much more efficient in comparison to traditional cutting methods(such as sawing, plasma and shearing). The era before was both manual and intricate procedures; just like, afterward laser cutting acquires a really hurried or sufficient impression. Furthermore, the laser machines ability to cut various grades of steel aluminum brass copper and non-metals plastics wood ceramics allows it cater for a range manufacturer.

The Use of Metal Pipe Laser Cutting MachinesPossessing a metal pipe laser cutting machines have a huge edge when it comes to being able to do mass production. Manufacturers will improve productivity and reduce labor & material cost with laser technology over manual cutting methods. Progressing to another level, when integrated into CAD (computer-aided design) and CAM software the cutting process becomes even more optimal reducing material waste resulting in cost-effective manufacturing.

Laser cutting is actually woven directly into the manufacturing/fabrication of thin-walled tubing. A revolution made for shops and engineering teams with lots to make, more ideas than time! Metal pipe laser cutting machine's different cutting modes include: beveling, chamfering and drilling as well as more detailed curvature of the shape or even welding mode in detail -- this is why it have a very high level customization possibility. Further, there is scarce material distortion and no thermal stress zones - a problem associated with previously used laser technology.

Stainless steel Pipe bending automatic controller Chrome steel pipe laser cutting machine peculiar project

Manufacturers that require precise, project-specific cutting can benefit from customized laser cutting systems for metal pipes. Many of these may also access machine vision, counterbalanced adjustable cutting heads or high-speed rapid-strike technology that work to the advantage of cut operations. That has the additional advantage that automated workflows can be executed to each level by adding other components like measuring systems, marking lasers or material handling.

To sum up, when the subject is metal pipe fabrication used laser cutting, implements a faster and cheaper alternative that provides manufacturers with an accurate cut in their metals. Laser cut metal pipes help manufacturers to achieve finer finished workpieces, less faults during manufacturing operations and can also be customized for a specific project requirements thereby increasing the level of productivity within the manufacturing sector.

are a leading manufacturer laser equipment with a robust research metal pipe laser cutting machinedepartment, with wealth of knowledge in field. We can customize our products to meet demands of each customer. have 100+ professional patents, 100+ patents, plus 100+ certificates, are in more than 100 countries and regions throughout the world.

J Iangpin metal pipe laser cutting machinea laser equipment manufacturer which specializes the production of laser equipment. wide spectrum laser equipment located to meet the requirements various kinds laser equipment.

focus on the entire process transaction from signing contract ordering processing metal pipe laser cutting machinemanufacturing progress.

are a top producer laser equipment. Therefore, place great emphasis the quality of product and its metal pipe laser cutting machine. laser equipment we offer backed by numerous internationally recognized certificates including ISO quality management system certifications, CE safety certificates other international certifications. These certifications ensure that laser equipment highly regarded in local market, but it also meets the requirements the market in global markets.