Looking for a welder that will increase safety and provide high quality in your welding projects? Do you want to optimize your welding process so that it can be more efficient and cost effective? Look no further, the amazing micro laser welder is your answer! The Most Exciting Advancement in Welding Technology | by TerrblyFunctionFlags | Medium

A premier micro laser welder, it boasts a number of advantages that set apart from traditional welding equipment. Firstly, it allows a faster and more exact welding procedure because it assures the best welds all over. In addition, with its low heat input it reduces the risk of problems like distortion and cracking that will maintain structural integrity to your projects. Moreover, it can weld just about any type of metal out there from the toughest mix like titanium and aluminum with perfect precision.

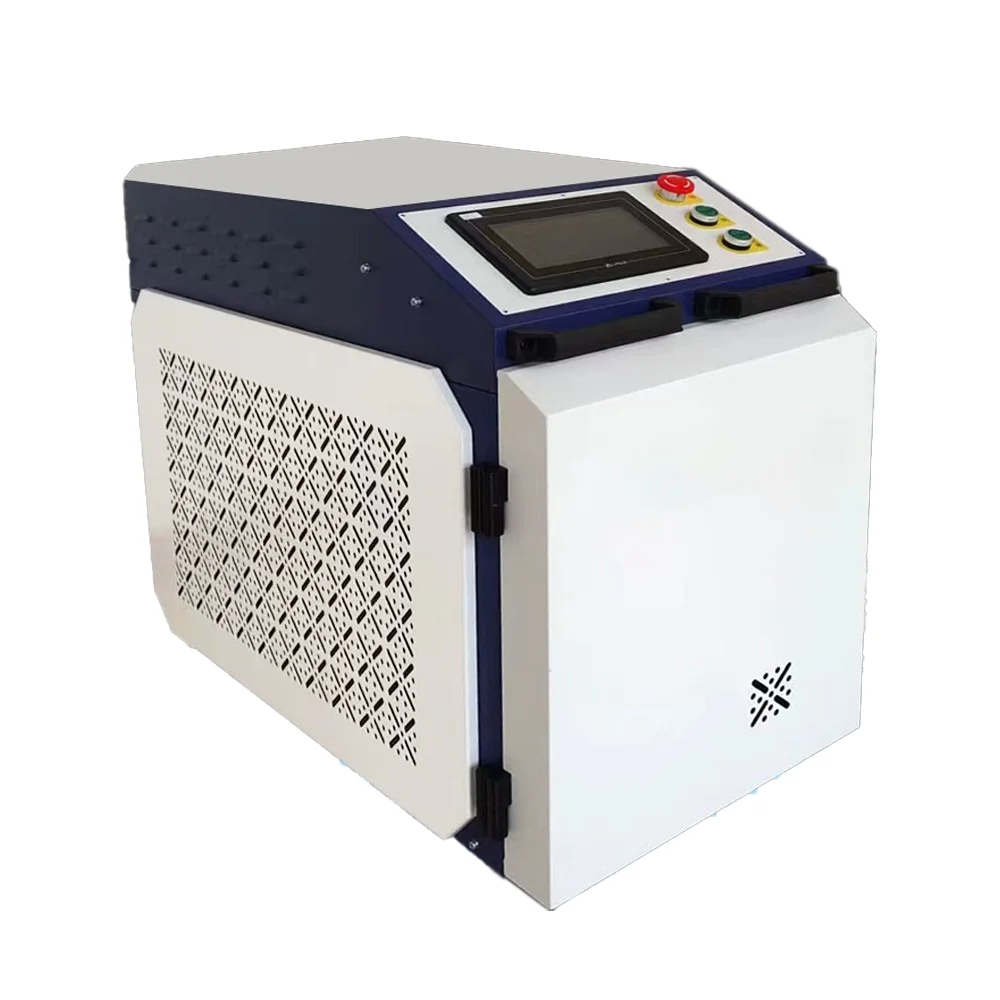

The equipment for the micro laser welder is innovative; taking advantage of cutting-edge in laser technology to produce perfect, high-quality welding. This tool prioritizes safety, so it has a sealed welding chamber that protects workers from dangerous emissions and ensures no toxic vapor or rays are released. Additionally, it has a highly precise laser beam that decreases the chances of getting burned, cut or otherwise injured in accidents common to traditional welding instrumentation.

This makes working with the micro laser welder a simple procedure which requires minimal training. Step one is cleaning the surfaces of all metals you are going to weld. As a consequence, you have to position the metals and set up the laser beam distance and angle. For instance, once the initial steps are done and it is time to start with welding process then simply go ahead with a micro laser welder. An arm on it will move and fire a small laser beam that welds the metals together.

Durable construction - The micro laser welder is a robust tool designed to endure the trials of this type of workspace, ensuring its long-term utility in your facility. Additionally, as part of the service offering a full servicing package is supplied which includes scheduled maintenance all repairs and upgrade replacement work. The micro laser welder can be your trustworthy welding partner for many more years with excellent care and maintenance.

J Iangpin Technology a laser equipment manufacturer that focused on manufacturing laser equipment. wide variety laser equipment can easily micro laser weldermeet demands different laser equipment.

team at the early stages of project that is -depth micro laser welderwith customers, provide expert advice technical solutions to personalize services. throughout process of transaction, concentrate on every aspect of follow-up and services experience, beginning with the moment of signing the contract, order processing, monitoring of the production progress up to the final factory inspection, the implementation of entire procedure of adjusting management of the whole process .

are a leading manufacturer laser micro laser welderwith robust research development team, as well as wealth of expertise in field. We can customize products to meet the specific requirements every customer. hold more than 100 professional patents, 100+ patents, and 100+ certificates, and service more than 100 countries regions across the globe.

a top laser equipment manufacturer attach a lot of importance product quality conformity. hold an array of internationally recognized certificates, which include but not limited to ISO Quality Management System certification, CE safety certification other international certificates, which guarantee that laser equipment not only widely accepted in local micro laser welderand has also the legal dependable qualification for market access in international market.

Because a micro laser welder can perform so many different types of welding, it is truly needed across a wide range of industries where the highest levels of welding accuracy are necessary for production. It is used in the field of medicine for welding small and fragile medical equipment or tools. This tool is very important in the aerospace industry since ace precision and strength are required when constructing an air craft. While in the automotive industry, it is used for welding engine and transmission components that require high quality as well with outstanding strength.