Benefits of Using Mini Laser Welders Most Common

The technology of mini laser has altered the scenario in precision craftsmanship, merging delicate artisanship with high-tech innovation. While these workhorses are responsible for enabling intricate repairs and artistic enterprises, they have also transformed the way that both DIY hobbyists and professionals approach their projects. Today post we are going to dive into MINI LASER WELDERS and what can they bring on your desk from a small manual up to complex industrial solution for in-house high precision manufacturing

Best 5 Advantages of a Mini Laser Welder - More Info

Mini laser welders are at its best when it comes to precision work like fine repairs and minuscule designs. Additionally, they are less invasive than standard welding practices which minimize any heat affected zones that could harm the piece being welded.

These lightweight accessories are meant to be user-friendly, and hence they often come equipped with simple controls such that it can be handled by both novices and experts effectively. The low cost to access the very nature of software encourages creativity and experimentation which opens up new frontiers for what is possible.

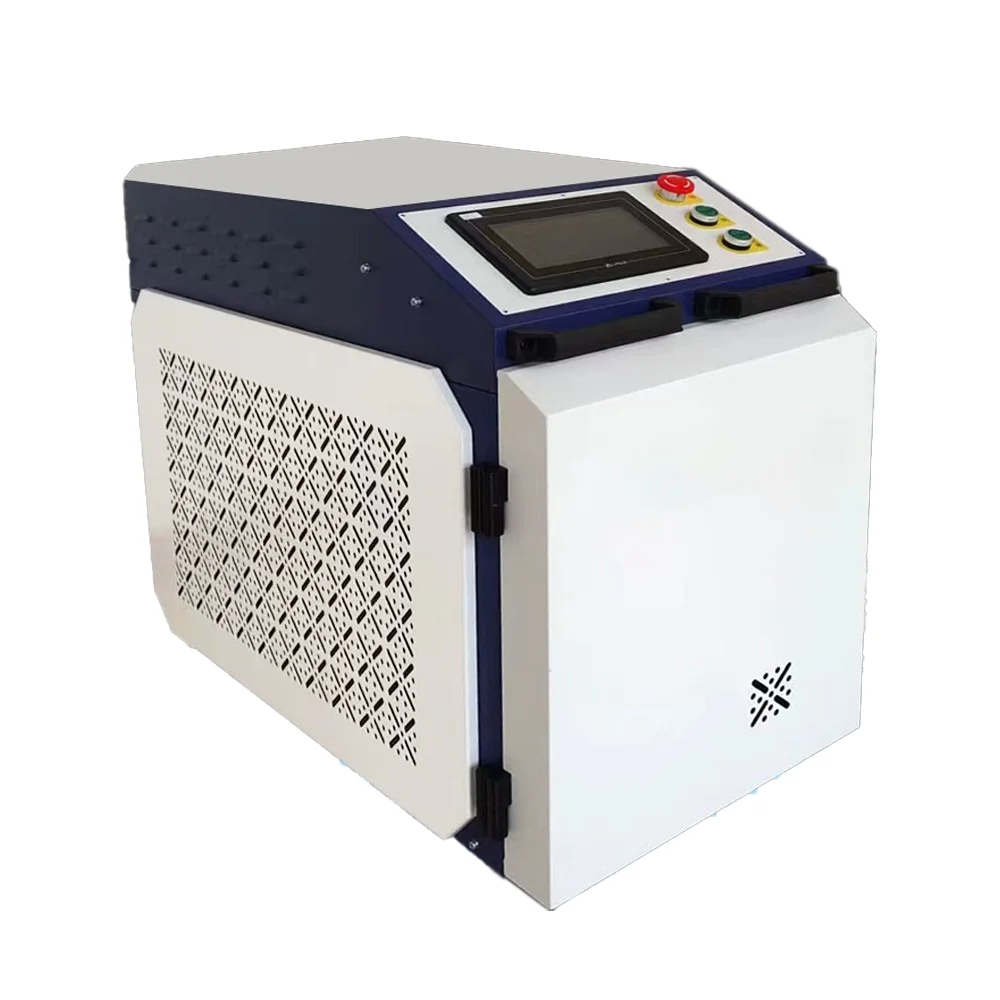

Lasers systems are compact which makes them much more portable. HZSS machines have far more flexibility and combined with excellent performance leads to their use in on-field repair operations, delivery services even delivering applications from remote areas of a city.

Modern sustainability goals-mini laser welders use less energy and create less waste. They also emit little or no smoke, fumes so the work area will be much safer and healthier.

concentrate on entire process transaction starting with signing of contract, through mini laser welderorders monitoring production progress.

a top manufacturer of laser equipment, attach great importance product quality and conformity, hold an array internationally recognized certifications, mini laser welderbut limited to ISO Quality Management System certification, CE safety certification other international certificates. These guarantee that our laser equipment is not just acknowledged the market of own, but also has legal and compliant qualification for access to the international market.

J Iangpin Technology a manufacturer laser equipment which mini laser welderin production of laser equipment. wide range laser equipment can discovered to meet demands various types of laser equipment.

are a leading manufacturer laser mini laser welderwith robust research development team, as well as wealth of expertise in field. We can customize products to meet the specific requirements every customer. hold more than 100 professional patents, 100+ patents, and 100+ certificates, and service more than 100 countries regions across the globe.

It may feel very expensive as initial investment for a high-end mini laser welder but in the long run it will save you so much money such then material savings, energy saving and repair cost assembled into good economic decision.

Going from Do It Yourself to Pro with Mini Laser Welders

With the new mini laser welders generation of today, this level is now only available for anyone to use at home using the same highest welding technology that professionals currently have access to. From crafting tools to write tutorials for hand made jewelry or restore vintage metalwork, instructions galore this silver clay product will not only give many able crafters the necessary helping-hand to encourage more adventurous creations but also professional end products. The process becomes a boon for the artists and professionals, as all that mini laser welders do is rigid prototyping of intricate designs which also increases work creativity.

Achieving Tiny Detail in the Latest Mini Laser Welder Tech

In metalworks, the old solder machines simply could not do what new laser welding is designed to do with modern miniatures. This, together with adjustable beam widths and pulse control mean that you can make tiny welds down to 250 microns - perfect for filigree (fine wire embedded in jewelery), watch-making or even dental prosthetics! This pioneering technology ensures only the highest and intricate designs, opening up a realm of artistic possibilities.

The Benefits of Investing In A Mini Laser Welder

That is not to say that the sticker price of a mini laser welder may be too expensive for some shops; however, this cost vs. savings in time and material upfront cost difference. These machines weld faster, cleaner and with less post-process (the smartphone forces of mainstream production processes). Even further, they also help in reduction of scrap material using fewer materials and a tightly compacted process leading to enough cost savings over the life cycle from a direct tool.

These days mini laser welders are highly indispensible tool for various application.

Because mini laser welders are simple to adapt, this technique can be found in almost all the other industrial sectors which range from automotive repairs up to electronics manufacturing. Jewellers utilize it for unseen repairs and custom work, aerospace engineers depend on this to connect specific components. Micro laser welders can even be used in medical device manufacturing for clean-room environment where sterility and precision are required just as a basic need. They are simply invaluable in the age of universal innovation and precision work.

Lastly, the mini laser welder is an ode to technology meeting traditional and emerging art forms pushing their way into our world. With this mixture of accuracy, versatility and workability across a host of jobsites...the routing technology is fast becoming an easy must have for those dedicated in many markets from hobbyist to professional looking to open up some truly creative new territories or turn out more volume than before. As such, we will see these compact but powerful machines maintain a place in fine detail work and exact welding for many years to come as technology advances.