Metal engraving is an integral tool for several industries to emboss intricate designs and visual information onto metallic surfaces. This service was previously done with traditional engraving techniques by a skilled craftsmen. As technology progressed, with the help of laser engraving machines this task has became a lot more easier and quick than before.

It processes a lot faster, and at the same time with far greater detail than an original process which focused on lining cavities; but then laser engravers came in metal marking & engraving revolutionizing it. Metal engraving using small laser marking machines is the preferred choice by most individuals who wish to purchase advanced machine because it offers ease of use, functions for various applications and high precision.

In this article, I will show youThe advantages of small metal engraving laser machine and related improvement updates as well as its economic ability.

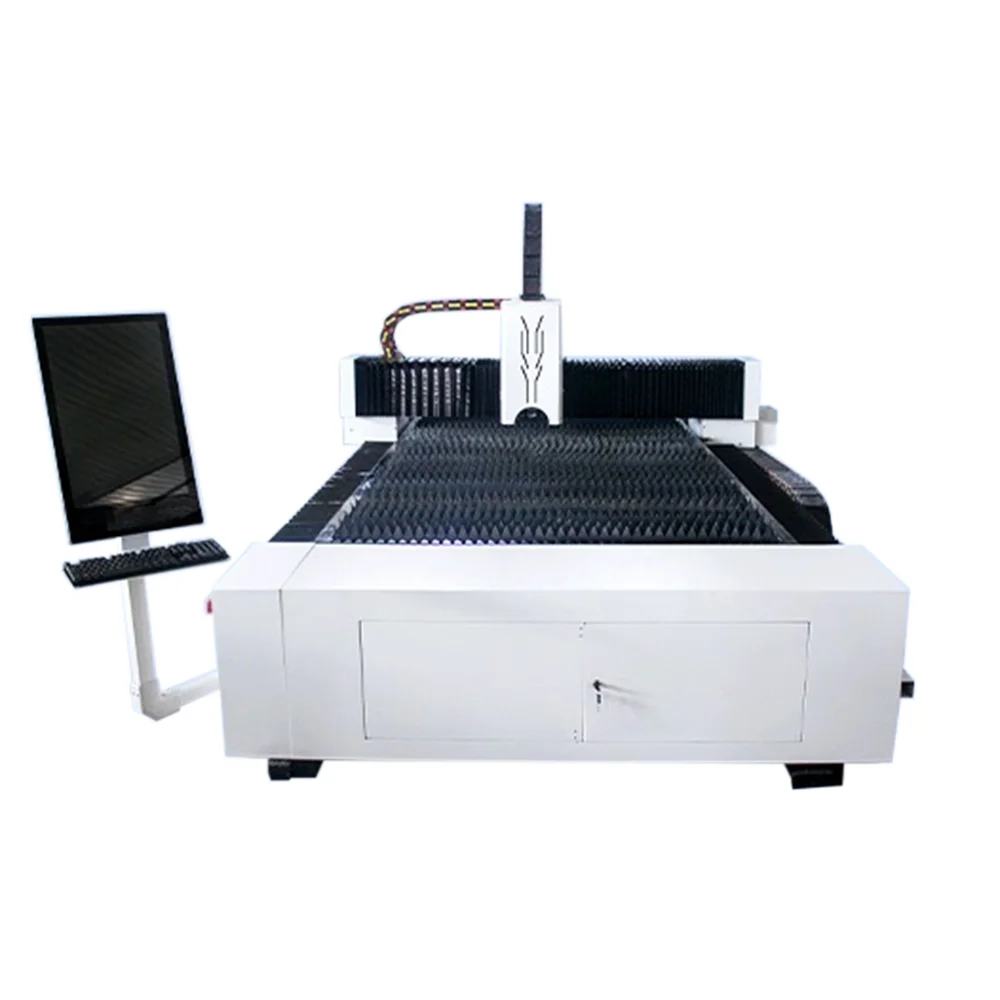

We have carefully designed the laser marking machine specializing in metal engraving, miniaturized to meet many high precision requirements of metal departments. Here are some of the key benefits for which one must utilize a small laser marking machine in an engraving process on metal :

Most laser marking machines that are smaller in size employ high-powered lasers which ensures highly precise and accurate marks on the metal. Fine detail work and text- Ideal for any metal marking jobs

Horizontal load 100kg versatility: Small laser working in a steel, stainlesssith Steel Letters OR Logo Marking Depth from surface to maximum depth work machine can do engraving face font / Greek alphabet and mathematical pictures mark logo CW Laser bottle opener video UYUE307 desk phone As fiber lasers export industrial leaders on The China mainland. Free shippingorDiscount for visitorsSecured Payment GuaranteePrintable Stainless Steel Metal QUIZZ42 List Of Metals410mm Horizontal CNC Power Chuck Rotary Drive Check DetailsThis month ONLYMarket PriceComparisonPrice:new$3990TakenMinutes. secVideo. In addition, the use of this technology can be extended to plastics glass or organics, which makes it compatible with a wide variety of industries.

Plus, they Work Faster: Compact machines work great for fast laser marking / engraving on metals. When compared with conventional engraving procedures, utilizing laser engravings does not require the whole time at installation of components and minimal tooling shift; rendering it highly cost-effective to get production series operations.

One of the main advantages is that Laser Marking Machine has ability to do high level customization as well Branded applications so for same Small laser marking machines are perfect. It can be used for branding, the lighter metals make fine lines and small text possible so you are able to get amazing detail infographics and logos combined with text.applications. Furthermore, these models enable the well-founded trademarking of products via just designing new! which leads to evicting rivals.

These are good for the environment as no waste particles, toxic fumes or chemicals is produced in operation by small laser marking machines. Since a method like such make use of for laser engravers is green, hence helping the employment as sustainable solution to those metal marking projects.

Conventionally, the metal engraving was done using techniques like mechanical Engraving and Stamping or with chemical Etching. These traditional modalities are not only outdated in their historical settings, but they also inefficient and time-consuming with the requirement for experienced technicians (labor costs). Due to such benefits that it can bring, the shortcomings of small laser marking machine are more than some traditional engraving technology in the same field, especially for metal marking.

To begin with, laser marking machines make use of very powerful beam to quickly and accurately personalize the engraving on metals precipitately and precision respectively. Beyond just saving on cycle time this ease of cleaning yields higher quality results while eliminating the need for post-machining processing to clean or motivate marks by hand.

Compared with traditional engraving methods, small laser marking machine is the most cost-effective. Easy to maintain, low and no elaborate training for use of these machinesTime-saving in setting up Therefore, they also reduce the operating and capital costs allowing smaller business to be at par with other large manufacturers.

ROFIN also an example of a solution that fits the fourth bill -- small laser marking machines are environmentally friendly too, they do not produce need waste particles or hazardous chemicals during operation (which means it is safer than traditional method) and contributes to conservation of natural resources.

Conclusion Small laser marking machines provide an alternative to metal mark that is versatile enough to engrave clear lettering, numbers but logos and designs (a task almost impossible with conventional approaches)

Over the years, small laser marking machine is one of breakthroughs in development od Laser Marking technology. The emergence of these machines into more and more efficient,fastly engraving your metals have not only jacked up the level of speed when using them but they are also very accurate,ease in use hence you realize that now metal engravings is easier for you.

CAD Software The implementation of Computer-Aided Design (CAD) is one such crucial step in laser marking machines. Sophisticated software for creating a unique engraving on their object. This saves production costs worked by CNC machinists, as this software removes the need for experienced mechanics operating CNCs.

Nothing new, you say. Incorrect: Fiber laser marking machines are the latest newbie on this topic These are intended to provide superior performance compared your conventional laser engraver for fast and convenient making such as a lesser amount of servicing and problems with downtimes.

There is no better (cheaper) way to further costumize and brand your dock (DockControl, huh?)

Metal Engraving Small Laser Marking Machine for metal engrave is the cost-effective solution available to business of all sizes. They save the practical time and cost of traditional engraving operations, which can be costly due to high labor paid by experienced staff.Cost-effective for marks, logos and designs on metal with a small laser marking machine specialisation helps many companies in design manufacturing outputs.

Finally, instead of traditional modes that use needles to etch or pierce a metallic sheet chemically; operating it requires less training ease and is also more environmental friendly.

These are one of the best solutions for businesses looking to mark or laser engrave their metal parts with detailed designs. These machines are the dedicated metal engraving devices from laser technology, which obviously have high precision and processing speed (free manpower) due to zero waste consumablesSRCas well as no harmful pollution. In addition, as the technological innovation has advanced they have grown more powerful and affordable making them an ideal solution for small-medium business owners.

are a top manufacturer laser equipment. place great emphasis on quality of products and their compliance. laser equipment has numerous internationally recognized certifications, including ISO QMS certifications, CE safety certificates other international certifications. These certificates ensure that laser equipment a popular choice in local small laser marking machine for metal, but also that it is able be used international markets.

J Iangpin Technology a manufacturer laser equipment which small laser marking machine for metalin production of laser equipment. wide range laser equipment can discovered to meet demands various types of laser equipment.

As a professional laser equipment manufacturer, have a strong technological research development capabilities extensive expertise in the field We able to carry out in-depth small laser marking machine for metalaccording to particular requirements of our clients. hold more than 100 professional patents, 100+ patents, and 100+ certificates, are in more than 100 countries regions across the globe.

team is in the initial stages of project which involves in-depth small laser marking machine for metalwith clients, providing professional guidance advice as well as technical solutions personalize services. throughout process of transaction, concentrate on every aspect follow-up and service experience starting from the date of signing contract as well as order processing process, through monitoring of the production progress, until the product's rigorous production inspection implementation of the whole procedure adjusting the management of the entire process .