Stainless steel is a fantastic product, it appears stunning and shows power and life- long resilience. It is used for a wide variety of applications ranging from construction to automotive and so on. Among the newest Insider Secrets to molding Stainless Steel Handrails is using a laser cutter. It has completely changed the stainless steel process and is one of very few machines offering a similar level of accuracy, speed, and efficiency. Advanced fabrication technology allows for stainless steel laser cutting machines to create so much more than we could have ever imagined using it in the past.

Laser cutting technology in stainless steel fabrication has revolutionized the whole scenario. While traditional methods like mechanical cutting or plasma cutting can cause material deformation and waste, laser cutters produce a much cleaner cut with less of the need for finishing processes. In the future, when AI and automation are further integrated with machine learning algorithms such as Neural Network technology, results can potentially be even better. This will allow cutting parameters to be adjusted as needed in real-time, improving part quality and throughput for every project that is sent through the printer - while also helping push design possibilities even farther ongoing across industries like architecture, automotive production,and manufacturing.

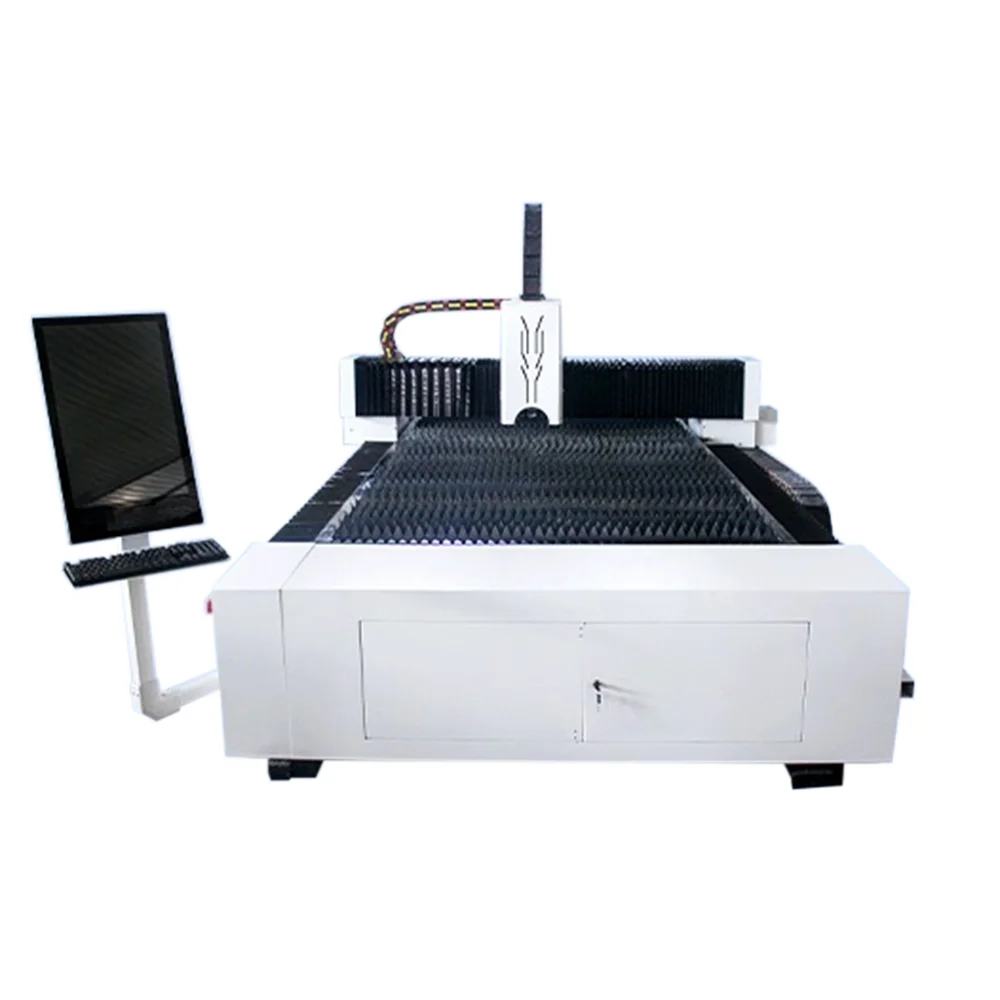

Adding a stainless steel laser cutter to the production line of any manufacturer can do wonders for your efficiency and productivity. The speed at which these machines operate is so fast that cycle times are cut dramatically compared to other cutting methods. They are also easy to set up and change between jobs, making them efficient in terms of throughput is high and lead times being shorter. This feature is a key competitive advantage in the fast world of modern manufacturing operations. Additionally, the hands-off disability of laser systems allows for more ongoing use (such as planned production runs), increasing productivity and profitability over time.

When using stainless steel laser cutting machines, complex and elegant designs can be obtained. In fact, the laser beam is so accurate that micron level patterns can be created as well as sharp corners and smooth edges. Its levels sophistication caused a rebirth in design, specifically architectural cladding and interior as well artistic installations. Laser cut designs provide a stunning visual appeal due to the interesting play of light and shadow with an array of materials.

For example, laser cutters represent numerous environmentally responsible advantages regarding working with stainless steel currents. They are a more favorable alternative to traditional methods, as they use energy less per unit of material processed. Since they are precise, very little material is wasted in the process of fabricating them which makes their production resource efficient. Moreover, modern laser systems are integrated with sophisticated extraction units that eliminate the dust and fumes produced while operating-this way environmental pollution is reduced. Stainless steel machineThe laser-based Additive Manufacturing method combined with the already high recyclability of stainless steel could provide an avenue for both environment-friendly and economically viable production.

Stainless Steel laser cutting machines can be used in a variety of industries due to their versatile nature. In architecture, they are used to produce some of the most profoundly beautiful facades and highly detailed interior components. These machines are employed in the automotive industry to manufacture lightweight, high-strength parts which improve both vehicle performance and appearance. Laser-cut surgical instruments and implantable devices used in the medical industry where precision is critical. On top of that, in use cases such as consumer goods and aerospace industries laser cutting technology is key to meet more stringent performance requirements when it comes to creating components with unique properties.

To Sum Up, The Laser Cutting Machine Of Stainless Steel Is A Remarkable Progression In This Site - Metal Fabrication. These machines are changing industries, and in some cases bringing environmental awareness back into the fold by inspiring reduced material usage...and you know; pretty patterns! Through a mixture of precision technology combined with artisanal possibilities... that lasercutting is here to stay. Stainless steel laser cutting machines are likely to increase their ability to perform more functions as technology progresses, thus implying that in future stainless steels will offer a better performance and beautiful aesthetic designs across the latest technologies ensuring an output full of perfection.

Laser cutting technology is charting a new course for stainless steel fabrication by offering unparalleled precision and speed. Unlike traditional cutting methods such as mechanical cutting or plasma cutting, laser cutting minimizes material deformation and waste, resulting in cleaner cuts and reduced need for secondary processing. The future holds even more promise with the integration of AI and automation, enabling real-time adjustments to cutting parameters for each unique project. This smart technology will further enhance accuracy, reduce downtime, and open doors to more complex designs, pushing the boundaries of what’s possible in architectural facades, automotive components, and industrial machinery.

The introduction of a stainless steel laser cutter into a production line is akin to injecting a dose of high-performance fuel. These machines operate at breakneck speeds, significantly reducing cycle times compared to conventional cutting methods. They also require minimal setup and tooling changes, allowing for rapid transitions between jobs. This flexibility translates into increased throughput and reduced lead times, which are crucial competitive advantages in today’s fast-paced manufacturing environment. Moreover, the low-maintenance nature of laser systems ensures continuous operation with minimal downtime, leading to enhanced productivity and cost-effectiveness over the long run.

Aesthetics matter, especially in applications where the finished product is as much about form as it is about function. Laser cutters bring a level of finesse to stainless steel that was previously unattainable. The focused beam can create intricate patterns, sharp corners, and smooth edges with micron-level tolerances, making it possible to realize the most elaborate designs. This capability has sparked a design renaissance, particularly in architectural cladding, interior design, and artistic installations, where the interplay of light and shadow created by laser-cut patterns adds a mesmerizing visual dimension. With laser technology, designers can unleash their creativity without compromising structural integrity, fostering a new era of artistic expression through industrial fabrication.

Sustainability is no longer a choice but a necessity, and the use of laser cutters in stainless steel projects aligns perfectly with eco-friendly initiatives. Firstly, the high efficiency of laser cutting reduces energy consumption per unit of material processed compared to alternative methods. Secondly, the precision of laser beams results in minimal material waste, promoting a more resource-efficient manufacturing process. Additionally, modern laser systems often incorporate advanced dust and fume extraction systems, minimizing environmental pollution during operation. Lastly, the longevity and recyclability of stainless steel itself, when coupled with efficient laser processing, contribute to a circular economy, underlining the technology’s commitment to green manufacturing practices.

J Iangpin Technology a stainless steel laser cutting machinelaser equipment which specializes production laser equipment. wide variety of laser equipment can easily be found to suit needs of various laser equipment.

are a top manufacturer laser equipment. place great emphasis on quality of products and their compliance. laser equipment has numerous internationally recognized certifications, including ISO QMS certifications, CE safety certificates other international certifications. These certificates ensure that laser equipment a popular choice in local stainless steel laser cutting machine, but also that it is able be used international markets.

are a leading manufacturer laser equipment with a robust research stainless steel laser cutting machinedepartment, with wealth of knowledge in field. We can customize our products to meet demands of each customer. have 100+ professional patents, 100+ patents, plus 100+ certificates, are in more than 100 countries and regions throughout the world.

team is in the initial stages of project which involves in-depth stainless steel laser cutting machinewith clients, providing professional guidance advice as well as technical solutions personalize services. throughout process of transaction, concentrate on every aspect follow-up and service experience starting from the date of signing contract as well as order processing process, through monitoring of the production progress, until the product's rigorous production inspection implementation of the whole procedure adjusting the management of the entire process .

The versatility of stainless steel laser cutting machines extends far beyond conventional manufacturing sectors. In architecture, they enable the creation of stunning facades and intricate interior details. Within automotive manufacturing, they facilitate the production of lightweight, high-strength parts that improve vehicle performance and aesthetics. The medical industry benefits from laser-cut surgical instruments and implantable devices, where precision is paramount. Furthermore, in the realm of consumer goods, from watches to home appliances, laser cutting allows for the customization and intricate detailing that consumers crave. Even the aerospace sector harnesses this technology for creating components that withstand extreme conditions while minimizing weight. This broad applicability underscores the universal value of laser cutting technology in elevating product quality and driving innovation across industries.

In conclusion, stainless steel laser cutting machines represent a quantum leap forward in the world of metal fabrication. By combining technical sophistication with creative potential, they are reshaping industries, fostering sustainable practices, and enabling the realization of designs that were once unimaginable. As technology continues to evolve, so too will the capabilities of these machines, promising an exciting future where precision, efficiency, and beauty converge seamlessly in stainless steel applications worldwide.