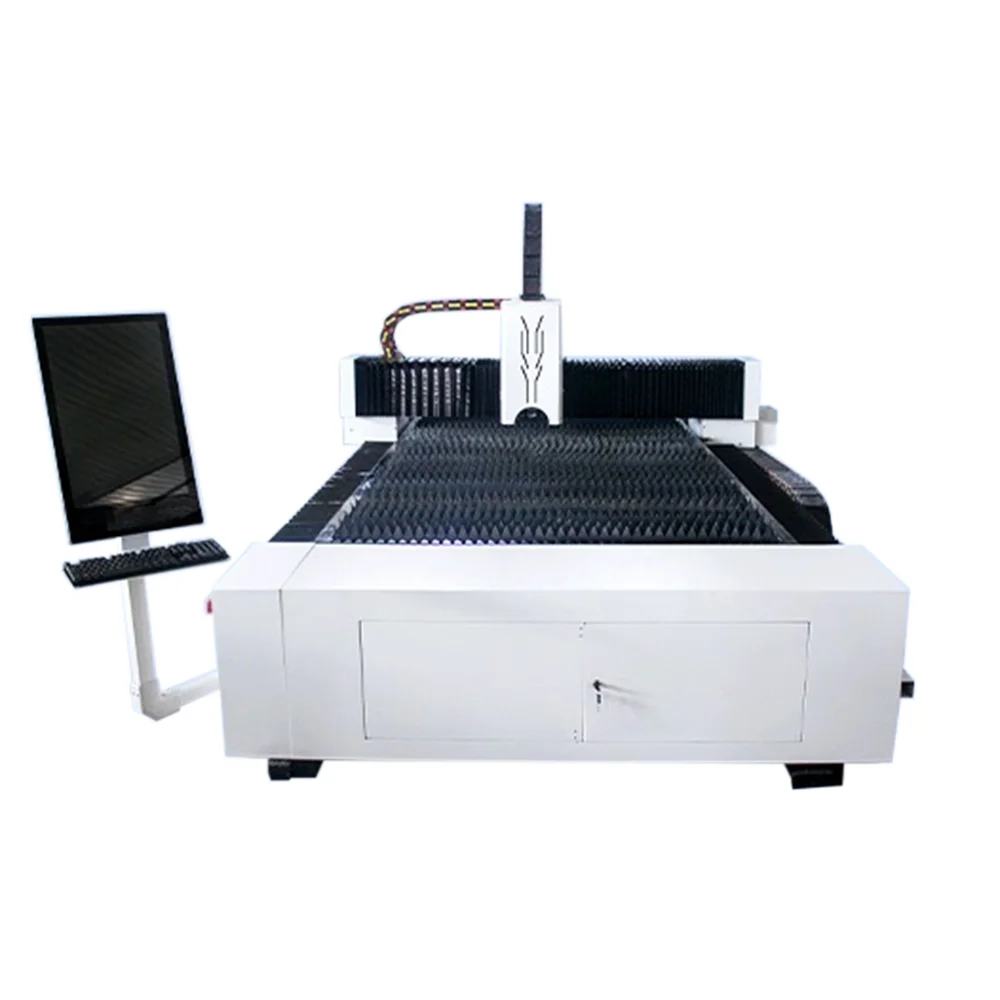

This particular tool is a metal laser cutting machine that utilizes the power of high-powered lasers to perform precise cuts in any steel component. They have a high level of precision that can be expected when cutting steel, which these machines are particularly good at done anticipate through any further means. This high level of accuracy is possible because a laser beam can produce an extremely tight focus - so the light that shines onto the workpiece effectively burns through even very thin sheets of steel.

A steel laser cutter is also an extremely quick option. Laser cutting technology is much quicker than many other traditional cutting tools which are also used for the same purpose, such as saws on steel and various metals; when producing a product these tend to take longer in size, this makes overall construction rates exponentially higher with lower production costs with use of lasers.

The latest development in laser cutting machines is their ability to be programmed and controlled remotely. Operators can use this feature to establish and coordinate the machine remotely from anywhere using a computer or another device. The laser of steel-casting cutting machines can also have an automatic focusing function, this ensures the focus position must be at the correct distance to reduce operation errors and improve accuracy in other models.

The safety of the operators is one thing you have to pay attention on while using a steel laser cutting machine. It included tools where protective covers were attached and interlocks that prevented the laser from operating if an operator was in its beam. In addition, a steel laser cut machine is equipped with several protective measures and an integrated exhaust system that directs the smoke and fume emitted during cutting towards this ventilation installation to prevent your workshop from being filled with dangerous vapors.

A steel laser cutting machine is the general kind of tool that can be utilized in many different aspects within industries. It features cutting & engraving of up to 3/4" steel, as well as pipe/tubing and a full line of assemblies Additionally, the CO2 laser cutter is capable of cutting an array of other materials like acrylics and woods or plastics meaning it can be a massive asset to multiple industries.

They are those who deliver desired shape and depth of the cuts, material cut etc so from my view as easy it is to work on steel laser cutting machine consists only this task which operator simply has to enter cut parameters along with. Once the machine is programmed, a sheet or tube of steel must be loaded by an operator to trigger cutting. The process is the responsibility of the operator, who must exercise this task after operating to ensure a workflow and leave that situation in error message for immediate action.

concentrate on entire process transaction beginning with signing contract and ending with order processing monitoring production steel laser cutting machine.

are a laser equipment manufacturer with strong research development department, with a wealth steel laser cutting machinein the field. can tailor our products to meet the requirements every customer. We are proud owners of 100+ professional patents, 100+ patents, and 100+ certificates, serve over 100 countries and regions around globe.

a top manufacturer laser equipment We attach lot of importance product quality compliance. have an array of steel laser cutting machinerecognized certificates, which include but not only ISO Quality Management System certification, CE safety certification and other international certificates, which ensure that our equipment isn't just accepted in local market, but also has the legal compliant qualification for market access in international market.

J Iangpin technology a reputable laser equipment maker that covers 2156 square meters. It has five product lines, which include vast range of steel laser cutting machinemodels, along a myriad of accessories satisfy clients' demands. Specialized laser production, company offers large array lasers satisfy the requirements of a range of laser equipment.

A steel laser cutting machine is a kind of machinery, all sorts of machinery need to be maintained regularly. This maintenance typically includes changing consumable parts, cleaning the machine and checking laser alignment / calibration. The quality of both the machine and support from service staff is paramount as well, so when determining what steel Tube laser cutting engraving equipment to purchase. Select a company that is known for building durable machines and providing great customer service.

Title Article: The application of steel laser cutting machine

Steel laser cutting machines have changed the way industries such as automotive, aerospace and manufacturing are using steel. Such amazing devices are essential for efficiently cutting and developing steel parts with unmatched precision/micron that involves gears as well as brackets, masses of other complex components.