Steel Sheet Laser Cutting Machine: The Advantages of Choosing Innovation and Safety

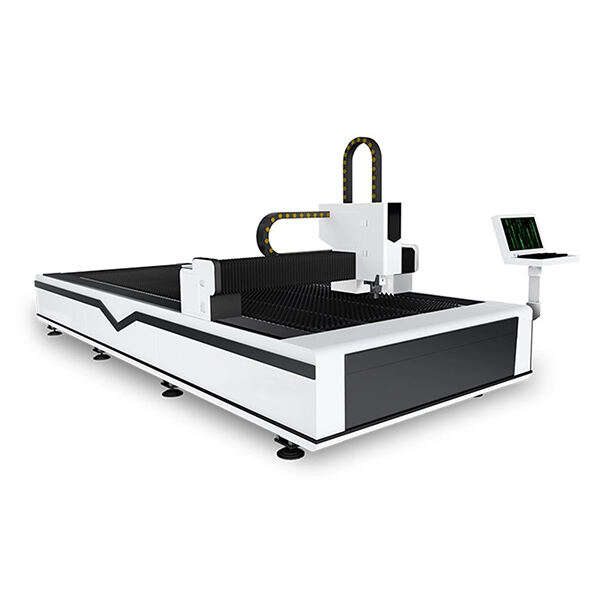

When it comes to cutting steel sheets, nothing works best than a laser cutting machine. We will discuss the advantages of using Jiangpin Technology metal laser cutting machine, its safety measures, usage, quality, service and application.

Using a Steel Sheet Laser Cutting Machine shows precision. Lasers cut through steels with accuracy, without burrs or rough edges. It can give you a high-quality finish and cleaner appearance product. It works fast in plasma cutting or water jetting which leads to faster production times and quicker delivery.

Steel Sheet Laser Cutting Machine is flexible. Jiangpin Technology stainless steel laser cutter can cut through different types of metals, such as stainless steel, aluminum, brass, and copper. You can make different products and form them based on your customer’s preferences.

The Steel Sheet Laser Cutting Machine allows manufacturers to work faster and with accuracy. Its design and software make it cut intricate shapes and designs seamlessly.

Laser cutting machines are created with safety in mind. It has protective enclosures that prevent the operator being exposed to laser beams and fumes. It is important to follow the safety rules and guidelines to ensure safety when using Jiangpin Technology metal sheet cutting machine.

The Steel Sheet Laser Cutting Machine is simple to use. The operator will put the metal sheet onto the machine's bed and program the Jiangpin Technology cutting sheet metal machine’s parameter using its software. Once the program is set, the laser beam will start cutting through the metal sheet based on the programmed design.

You need to follow simple steps in using the Steel Sheet Laser Cutting Machine. First, make sure that the machine is well-maintained and working correctly. Second, clean the metal sheet before putting it on the machine's bed. Third, use the software to set the machine's parameters. Finally, start the Jiangpin Technology cnc steel laser cutting machine and it will start cutting. Remember to monitor the process to ensure it is running smoothly and accurately for the best product result.

are a world-class producer laser-related equipment. This why we have strong focus on product quality conformity. laser equipment is backed by a number internationally steel sheet laser cutting machinecertificates, such as ISO quality management system certifications, CE safety certificates other international certifications. These certifications assure that not only our laser equipment highly regarded the market in the US, but also that it is able be used in the international market.

team at beginning stages this project that is in-depth communication with our steel sheet laser cutting machineprovide professional consulting advice technical solutions to customize services, during transaction process, focus on each link to follow-up as well as service experience starting from the date of signing the contract as well as the order processing process, through tracking the production process and, after product's strict production inspection and implementation the whole procedure adjusting the management of the entire process .

J Iangpin Technology a laser equipment manufacturer that is specialized in manufacture laser equipment. wide selection of laser equipment can steel sheet laser cutting machineto meet requirements different kinds of laser equipment.

a reputable laser equipment manufacturer, have strong technical research development strength extensive experience in business as well as the ability to provide full-scale customization to particular requirements of customers. have steel sheet laser cutting machinenumerous patents and certifications, employ more than 100 professionals, cover 100+ nations and regions across globe We also have 5000+ large cooperative customers!