Pastāv noteiztais veids kā svarīgs, kas padara mašīnas ilgāk. Šis īpašais savienošanas veids sauc par lasersvārstu. Piemēram, ir Jiangpin Technology, uzņēmums, kurš izmanto šo tehnologiju. "Lai padarītu tos stiprākus un labākus, un tas ir svarīgs klientiem, kuri uz to atkarīgi, tie izmanto lasersvārstus."

Kā darbojas lasersvārstīšana

Tas ir metode, kā savienot divus metāla daļiņas, kas veicota ar ārkārtīgu uzmanību un precizitāti. Tā izmanto cietu gaismas staru, kas sagriež metālu un saņēmēja daļu kontakta punktā. Sasilis metāls pēc dzesēšanās atkal izzūd. Tas veido ļoti spēcīgu saikni starp abām metāla daļām. Dēļ tās precizitātes lasersvaidzana spēlē arī būtisku lomu, lai saglabātu metālu spēcīgu un ilgtspējīgu, īpaši mašīnām, kas paredzētas sniegt uzticamu darbību.

"Lasersvaidzana — aptur karstu"

Rūsts ir nozīmīgs jautājums metāla objektiem, un tas notiek, kad dzelzs audzē siltā vidē un iegūst gaisu. Rūsts stipri mazina metālu un var izraisīt mašīnu straujo sabrukumu, ja tas veidojas. Laserdzelzs savienošana novērš rūsta veidošanos. Šis konkrētais process prasa arī mazāk siltuma nekā parastā dzelzs savienošana, tādējādi samazinot risku, ka metāls būs sadalīts. Metāls, kas ir sašķiebts vai deformatēts, var attīstīt vājus punktus, kas ir vairāk pieskarīgi rūstam. Saskaņā ar Jiangpin Tehnoloģiju oficiālo mājas lapu, to kombinējot ar laserdzelzs savienošanu, viņu mašīnas kļūst izturīgākas un mazāk pieskarīgas rūstam, lai klienti ar aprīkojumu varētu viegli par to uzturēties.

Mazāk laika pavadīts remontos

Nedarbības laiks ir tad, kad ierīces nestrādā. Tam var būt vairāki iemesli; vai nu tām nepieciešams kāds remonts, vai arī tās vairs nav nekādas izmantošanas. Uzņēmumiem katrs nedarbības minūtes ir dārgs, jo tie zaudē vērtīgu laiku, kad to mašīnas nestrādā. Tad ir lasersvīde, kas ir ātra metode, lai savienotu metāla daļas. Tas ir ātrāks nekā tradicionālie savienošanas veidi, kas nozīmē, ka mašīnas var atgriezties dienesta laikā ātrāk. Tas uzņēmumiem taupa naudu remontos un dod iespēju izpildīt vairāk darba bez pārtraukumiem, kas ir kritisks faktors straujā vide.

Lasersvīde labākiem aparātiem

Lazeru svars tehnoloģiju attīstība dod labas iespējas uzņēmumiem, piemēram, Jiangpin tehnoloģijai. Tas ļauj tiem izstrādāt jaunas un uzlabotas mašīnas dizainu, izmantojot šādas inovācijas. Piemēram, lietojot laseru svars, ir iespējams projektēt metāla daļas, kas ir plānākas un vieglākas. Tas ir labs ziņas, jo vieglāki komponenti ļauj mašīnām strādāt ātrāk un patērēt mazāk materiālu. Precīzi, ražojošo uzņēmumu materiālu taupīšana var novest pie zemākiem ražošanas izmaksām. Tas ir arī ekonomiskāk un var palielināt kopējo aprīkojuma efektivitāti.

Mazāk problēmu ar svārstību

Nepareizi veikta svārstīšana var izraisīt kļūdas, kas padara mašīnas vājāk. Jebkurā iekārtas neizpildes vai sabrukuma gadījumā nav ko vēlas neviena uzņēmums, un tas noved pie šo vājo punktu radīšanas. Sniedzot stipru un uzticamu svārstīšanu, lasersvārstīšana samazina šo svārstīšanas problēmu risku. Kā rezultātā mašīnām nepieciešams aizvietošanas process mazāk bieži, kas uzņēmumiem ilgtermiņā nodrošina lielu naudas ietaupījumu. Tā kā lasersvārstīšana palīdz samazināt šādas problēmas, tā veicina mašīnu neatkarīgu un efektīvu darbību tiem, kas tās izmanto.

Kopsavilkums

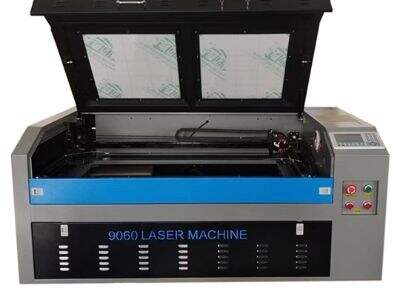

koka lāzera gravēšanas mašīna ir jauns veids tehnoloģijā, kas var tikt izmantota, lai izveidotu stiprus un ilgtspējīgus mašīnas uzņēmumiem, piemēram, Jiangpin Technology. Tas ir būtisks dalībnieks mašīnu uzturēšanā un patiesībā palīdz samazināt remontu izmaksas, kā arī paaugstināt darba efektivitāti. Jiangpin Technology uzlabo savu mašīnu darbības spēju un ilgtspēju, izmantojot lasersvaidi. To klienti taupīt naudu, un uzņēmums joprojām gūst lielākus peļņas apjomus, tas ir uzvaras situācija visiem iesaistītajiem.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

BE

BE

AZ

AZ

KA

KA

LA

LA

UZ

UZ