The Innovative Way to Connect Fibers.

The fibers are fused together using heat, which results in a strong and permanent connection. This connection has low insertion loss, meaning there minimal attenuation of the light signal through the joint, resulting in better quality of data transmission. The Jiangpin Technology company produced a fiber optic laser welder to ensure alignment of the fibers, which essential for optimal performance. Precision particular important for high-speed internet connections and other critical applications. Fiber welders are fast and efficient, and the process takes a few seconds. It even possible to weld different types of fibers together, such single-mode and multimode, or dissimilar diameter fibers.

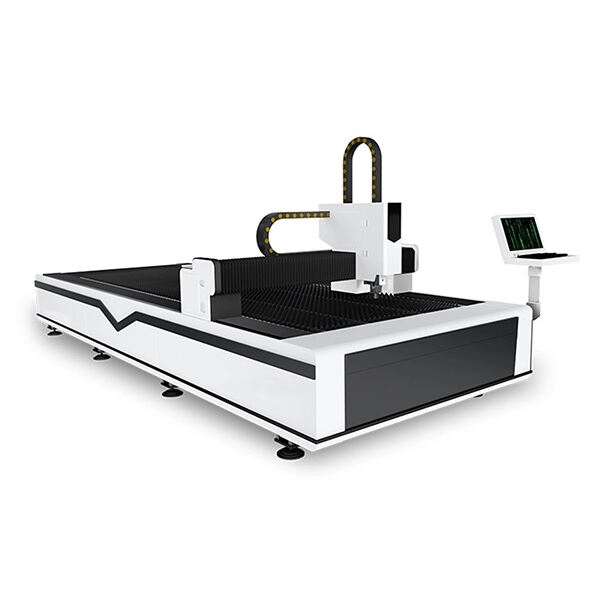

Some of the latest fiber laser welding machine feature automated alignment technology makes it easier to achieve a perfect fusion. The Jiangpin Technology company ensures the fibers are accurate aligned, regardless of operator skill level. The latest fiber welders come with high efficient heating systems ensure a faster and more reliable fusion. These systems can fire within two seconds, speeding up the entire process significant.

Protective Eyewear for fiber welder come with a built-in safety mechanism prevents the high-intensity light from reaching your eyes. However, it's still essential to wear protective eyewear Jiangpin Technology company added safety equipment. Automatic Shutoff If the fiber welder starts to overheat or detects a fault, it will automatic shut off, preventing any potential damage or injury.

Prepare the Jiangpin Technology laser fiber welding machine. Strip the coatings from the fibers to expose about 3cm of the bare fiber. Use a cleaning solution to clean the fibers and remove any dirt, dust, or oil. Align the fibers put the fibers into the splicer's alignment mechanism and adjust them for perfect alignment. Once the fibers are in perfect alignment, initiate the heating process, and let the fibers fuse together.

concentrate on entire process transaction beginning with signing contract and ending with order processing monitoring production fiber welder.

J Iangpin fiber weldera laser equipment manufacturer which specializes the production of laser equipment. wide spectrum laser equipment located to meet the requirements various kinds laser equipment.

a leading maker of lasers, have a strong technological research development capabilities as well as extensive experience in fiber welderas well as the ability provide a full-scale customization to the requirements of customers. We have secured numerous patents and certifications, employ 100+ professionals, serve 100+ countries and regions worldwide have over 5000 large customers who cooperate with us!

a top manufacturer of laser equipment, attach great importance product quality and conformity, hold an array internationally recognized certifications, fiber welderbut limited to ISO Quality Management System certification, CE safety certification other international certificates. These guarantee that our laser equipment is not just acknowledged the market of own, but also has legal and compliant qualification for access to the international market.

Fiber welding a precise and delicate process requires the right tools and experience. So, before you invest in a fiber cutting machine, it important to ensure you have the right support in terms of service and quality. Here are some things to consider: Look for a fiber welder with good build quality and high performance. Check the specifications to ensure the welder meets your specific needs. Choose a supplier offers excellent service and support, including training and ongoing technical support.